It’s easy to say you’re a leader. But much harder to become one — and stay one. It takes work.

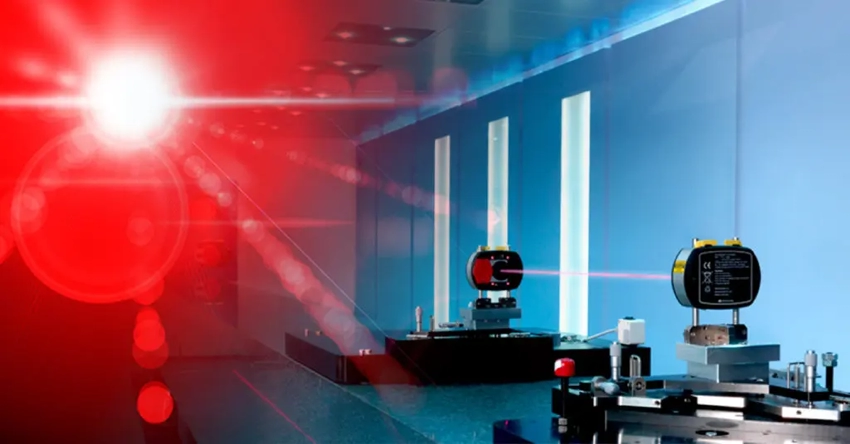

To date, the legacy of PRUFTECHNIK, a division of Fluke Reliability, covers nearly 50 years of industry-leading expertise and transformative products. We invented the laser shaft alignment category and continue to innovate — delivering the industry’s first and only systems that adapt to any alignment task, asset, or user experience level.

As the world leader in alignment solutions, our innovations have been copied but never successfully matched.

Building trust

Like many companies, PRUFTECHNIK formed in 1972 because it recognized an opportunity to solve longstanding industrial machinery maintenance problems. Starting with our first product, the company began building a reputation for innovative solutions. A constant string of product “firsts,” including the invention of single-laser technology, cemented our position as the industry leader.

Here are just four of the landmark changes we have introduced over the years.

Four game-changers

- OPTALIGN: First laser-optical shaft alignment system in the world

- ROTALIGN: First shaft alignment system with SWEEP measurement method and dedicated DIM-M-RES workflow

- PARALIGN: First inertial parallelism measurement system for the alignment of rolls

- Adaptive Alignment systems: First laser shaft alignment solutions with single-laser technology and Active Situational Intelligence (ASI), which trigger their adaptability.

Major turning points

Early on, PRUFTECHNIK recognized the power of cloud-based software in enabling data sharing and team-based collaboration. We blazed new trails by integrating cloud connectivity into our products. We continue to regularly fuel research and development with innovations, many of which are patented.

Each new generation of our laser shaft alignment products has addressed seemingly unresolvable and relentless movement and measurement issues. By continuing to add inventive and highly advanced functionality using PRUFTECHNIK patented technology, our shaft alignment systems stand as the industry’s only ones capable of adapting to the situation, the asset, and the user skill and experience level of team members.

What’s so magical about Adaptive Alignment?

Adaptive Alignment system “magic” only happens when two critical elements unite—single-laser technology and Active Situational Intelligence (ASI). It is these two features (think brains and brawn) that enable the PRUFTECHNIK shaft alignment systems to adapt to the application, asset, and maintenance team member—in real time. Other laser alignment systems can’t fully adjust in this way.

Adaptive Alignment:

- Adapts to the situation by automatically adjusting to common challenges such as coupling backlash, environmental conditions, and gross misalignments quickly to assure precisely aligned shafts.

- Adapts to the asset, including virtually all rotating machinery, from motor pumps to more sophisticated equipment such as machine trains, gearboxes, and Cardan shafts. ASI software provides “in the moment” feedback and direction to maintenance teams.

- Adapts to the user level, such as a lesser-experienced technician who inadvertently makes errors in aligning a shaft. With ASI, inaccurate data is automatically removed in real time using analytics.

Adaptive Alignment unleashes your team’s capacity to restore assets to peak performance, expands support for a broader range of critical rotating asset types, and empowers your technicians to complete highly precise alignments faster and easier.

See the comparison chart to the right/left for some examples of how PRUFTECHNIK adaptive shaft alignment systems differ from others.

| Contact UsIf you’d like more information on PRUFTECHNIK, click here to go to the Contact Page. |

Four ways Adaptive Alignment differs from other alignment systems

| Single-laser Adaptive Alignment systems | Other laser shaft alignment systems |

| Require only one move to align a shaft, whether it’s a small job or a complex one. | Most systems require a pre-alignment when encountering a gross misalignment, making it necessary to move machinery at least twice to align the shaft. |

| Contain built-in Active Situational Intelligence (ASI), detects backlash during the continuous sweep, and automatically eliminates compromised readings without jeopardizing measurements. | Non-adaptive systems cannot filter out backlash, making measurements unreliable and increasing the risk of another misalignment. |

| Enable all levels of technicians to handle complex assets, gross misalignments, or other difficult situations. ASI software automatically corrects common errors to ensure highly reliable results the first time. | When alignments are complex, technicians often must guess or perform rework; worst case, the maintenance team opts to live with the misalignment and the potential for machinery destruction. |

| Technicians share alignment data instantly via the cloud enabling collaboration with team experts across the globe to ensure precise shaft alignments. | Other systems cannot share shaft alignment measurements instantly. The function and software that enables the capability are exclusive to PRUFTECHNIK. |

Maintenance leaders seek out PRUFTECHNIK laser shaft alignment systems because they work. We continue to innovate to advance our products and meet industry demands.

In 2019, PRUFTECHNIK was acquired by Fluke Corporation, the world leader in electronic tools and software for measuring, managing, monitoring, and optimizing asset performance. The two organizations share many things in common — foremost is providing transformative solutions to keep your world turning.