Technology and advanced tools are enabling maintenance teams to address shaft misalignment faster and easier.

Shaft misalignment happens when two rotating shafts are not parallel to one another. This kind of machinery misalignment is extremely common in rotating equipment and is often the root cause of failure.

The good news is that today’s shaft alignment tools make it faster and easier to identify misalignment in motors, pumps, blowers, and fans. Once shaft misalignment is diagnosed, these same shaft alignment tools also make it easier than ever to fix the problem and complete a precise machinery alignment.

5 Types of Machine Misalignment

Experts generally agree on five types of machine shaft misalignment. However, the reality is that alignment issues are often a combination of multiple types of misalignment, also called a compound misalignment. Here are the five:

- Parallel Misalignment Parallel misalignment happens when the two shafts to be aligned have centerlines parallel to each other, but the centerlines are offset.

- Vertical Angle Misalignment Vertical angle misalignment is a misalignment of two shafts in the vertical plane.

- Horizontal Angle Misalignment

Horizontal angle misalignment is a misalignment of two shafts in the horizontal plane. - Combined Vertical Angle and Offset Misalignment The combined vertical angle and offset misalignment occurs when one shaft is at an angle with another shaft, but both shafts still operate in the same vertical plane.

- Combined Horizontal Angle and Offset Misalignment The combined horizontal angle and offset misalignment occurs when one shaft is at an angle with another shaft, but both shafts still operate in the same horizontal plane.

Under normal conditions, shaft alignment is achieved when the positioning of the rotational centers of two or more shafts is arranged in a single straight line, both horizontally and vertically.

What Causes Shaft Misalignment?

These are the main causes of machine shaft misalignment:

- Settling of a baseplate resulting in soft foot

- Shaft deformation caused by torsion during startup

- Insufficient or poor-quality alignment measurements due to human error

- Pipe strain that leads to parallel and angular misalignment

- A thermal expansion that can make one piece of equipment move proportionally to another

Misalignment of shaft centerlines can give rise to shaft wobbling and significant vibration, leading to seal damage and bearing and coupling destruction. Identifying misalignment and the underlying causes is imperative if a machine is to reach its expected life.

4 Ways to Detect Shaft Alignment Issues

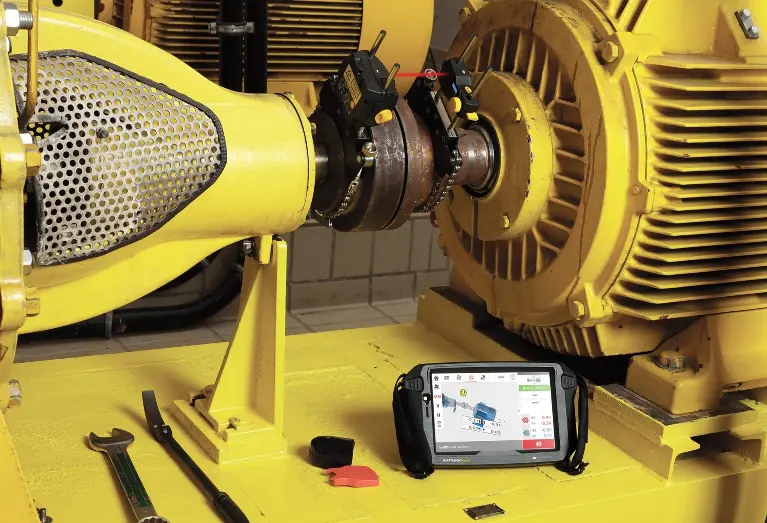

- Diagnosis via laser shaft alignment system

Checking for shaft misalignment is often the first course of action when a machine starts having a problem. A laser shaft alignment system determines misalignment at the coupling and calculates the appropriate machine movement to be performed at its base. Laser shaft alignment systems provide real-time, accurate, and precise measurements that tell you exactly when alignment is achieved.

Laser shaft alignment systems can be either dual or single laser types. However, a dual laser alignment system is not as capable as a single laser system. Often, technicians find it hard to maintain the line to the detector when trying to correct an angular misalignment. Unfortunately, as the measurement distance increases, so does the difficulty. As a result, technicians must restart measurements that require them to stop, loosen the feet, move the machine, and retighten the feet—all with no guarantee that the detector will then be in range. With every repeat, process time increases, and the potential for error grows.

A single laser alignment system removes all of the dual laser system’s problems. It addresses most any shaft alignment challenge, whether it’s straightforward or complex, such as a vertical flanged machine with right-angle gearboxes. A single laser system leverages two optical detector planes in a single sensor, eliminating the technician’s need to stop, loosen, and retighten feet, or repeat measurements. Single-laser technology enables precise, swift completion of alignment tasks.

- Vibration analysis

Vibration monitoring and vibration analysis have become more commonplace in recent years because of the speed at which modern data collectors can process triaxial sensor signals. Every machine has its level of normal vibration, but there are instances when machine vibration increases or exceeds acceptable parameters.

Some of the reasons for vibration increases include looseness, resonance, unbalance, and of course, misalignment. Vibration is most often measured by using accelerometers, followed by proximity sensors or velocity transducers. Once these signals are acquired with a data collector and sensors, a vibration analyst can further diagnose the machine faults.

- Thermography

Thermography can provide early detection of alignment issues by identifying abnormal hot spots. Misalignment can cause an increase in friction within a machine and, therefore, an increase in temperature. A thermal imager detects and measures an object’s infrared energy and turns the infrared data into an electronic image showing the object’s apparent surface temperature.

- Oil analysis

When condition monitoring detects an abnormality through oil analysis, immediate actions can be taken to identify the root cause or to act on the emerging failure. Oil analysis can help detect misalignment by providing the general condition of an asset, oil, and contaminants. Oil analysis can be complicated; as a result, many organizations use specialty companies to do the work.

Shaft misalignment causes a variety of symptoms and severe machinery issues. Implementing a preventive maintenance routine to verify precise machinery alignment will save money and time. By keeping shafts aligned, you also improve energy efficiency, increase uptime, and maximize production output.

Learn more about misalignment and how to correct it by reading this white paper.