What is Pump Alignment?

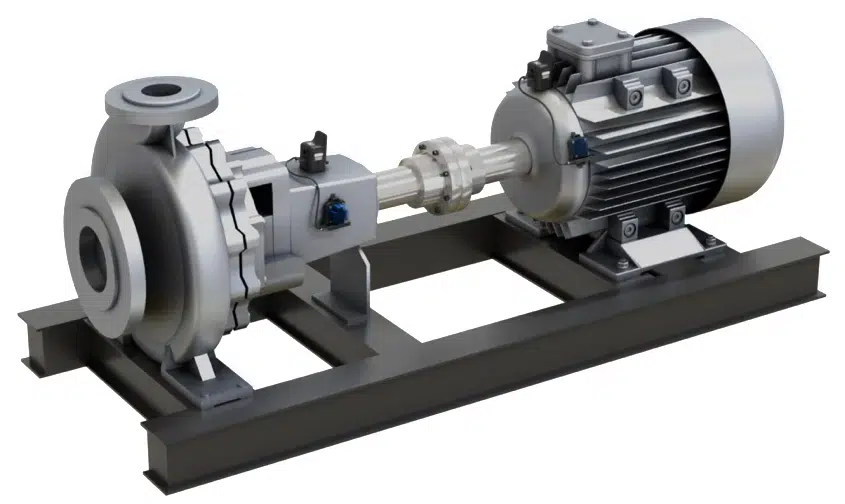

Pump alignment is the precise process of adjusting the positions of a pump and its driving motor so that their rotational axes are perfectly aligned. This alignment is essential for efficiently transferring power from the engine to the pump. It ensures that the system operates smoothly with minimal mechanical stress.

How to Align Shafts

Shaft alignment is crucial for the operational efficiency of pump systems. It verifies that the rotational axes of two adjoining shafts are collinear when the machine is running under normal conditions.

Misalignment, whether angular or parallel, can lead to various mechanical issues and inefficiencies. Here’s a typical step-by-step view of what’s involved in to aligning shafts:

- Initial inspection: Begin by thoroughly inspecting the pump and motor. Check for any signs of wear, improper installation, or damage that could affect alignment. Ensure that all components are secure and in good condition, as well as that the bolts are accessible and couplings are in good condition.

- Rough alignment check: If you’re using a dual laser alignment tool, you first need to use other alignment techniques to achieve a rough alignment. This initial step helps identify significant misalignment issues and make preliminary adjustments to bring the shafts closer to alignment before using precision tools.

- Measure with precision tools: If you’re using a single laser alignment tool, like the Prüftechnik RotAlign Touch, you don’t need to begin with a rough alignment. Single laser alignment systems precisely measure misalignment by providing data on horizontal and vertical planes. Laser alignment tools do require that you input accurate measurements, however, smart tools like RotAlign can help walk you through this process.

- Make adjustments: Based on precise measurement data, taking into consideration thermal growth, adjust the position of the driver – typically the motor. This may involve solving soft foot, shifting the machines horizontally or vertically. Best practice is to solve the vertical alignment prior to beginning the horizontal alignment, but a quality laser alignment tool will provide you with live move data. This is accomplished by adding or removing shims under the machine feet for vertical alignment and tightening or loosening bolts to achieve the desired alignment.

- Final verification: After adjustments, re-measure to ensure the alignment is within the manufacturer’s recommended tolerances. The verification of repeatable results is critical to confirm the alignment process was successful. Repeat adjustments as necessary until the desired alignment is achieved.

Pump Alignment Techniques

Effective pump alignment incorporates various techniques, each suited to different situations and precision levels:

- Straight edge and feeler gauge method: You can use this method to manually check alignment. Place a straight edge across the coupling and using feeler gauges to measure the gap between them. This method is simple and requires minimal equipment, although it tends to be is significantly less accurate than other methods.

- Dial indicator method: This more advanced technique uses dial indicators for precise misalignment measurements. It involves mounting one or two dial indicators on the pump and motor shafts to measure radial and axial movement. The dial indicator method is highly accurate and can detect both parallel and angular misalignment. However, it requires significant skill and understanding of the measurement process, as well as experience.

- Laser alignment systems: The most advanced and efficient technique uses laser beams and sensors to measure shaft alignment. Laser alignment tools offer high precision, quick setup, and easy-to-interpret results, making them ideal for ensuring optimal alignment. They can significantly reduce alignment time and improve accuracy, making them a preferred choice for many professionals. This option is the preferred method for the expertise constrained.

Pump Alignment Benefits

Proper pump alignment is not just a technical necessity. It creates tangible improvements to the lifespan and overall operation of your equipment.

Here are some of the major benefits of correcting pump misalignment:

- Optimized operational efficiency: Correct alignment minimizes energy loss and ensures pumps operate at peak efficiency, reducing electrical consumption and operational costs.

- Enhanced equipment longevity: By reducing mechanical strain on the shaft, bearings, and seals, proper alignment extends the lifespan of these components.As a result, the overall service life of the equipment increases.

- Improved system reliability: Proper alignment reduces the likelihood of mechanical failures, unexpected downtime, and safety hazards. This leads to a more reliable and consistent operation.

- Noise and vibration reduction: Correct alignment significantly reduces vibrations and noise levels produced by the equipment, contributing to a safer work environment.

Pump Alignment Checklist

To ensure a thorough and effective pump alignment process, consider the elements on this checklist:

- Lockout/Tagout (LOTO) procedures: Always adhere to safety protocols by ensuring all equipment is properly shut down and locked out before starting any maintenance process.

- Inspect equipment condition: Examine the pump, motor, and related components for any signs of damage, wear, improper installation, or pipe strain that could affect alignment.

- Verify tool calibration: Ensure all tools, especially sophisticated devices like laser alignment tools, are correctly calibrated and functioning as expected.

- Base and foundation check: Assess the condition of the baseplates and foundations for stability and integrity, as these can influence alignment accuracy.

- Bolt and coupling inspection: Examine the tightness and condition of all bolts and couplings involved in the alignment process. Inspect for bolt bound conditions.

- Cleanliness and obstruction removal: Clean all components and remove any debris or obstructions that could interfere with the alignment process.

- Record-keeping: Document all measurements, adjustments, and final alignment values for future reference and maintenance planning.

Following these detailed steps and considerations ensures that you’ll align pumps with precision. Doing it right the first time leads to enhanced efficiency, reliability, and longevity of pump systems.

Pump Alignment, Pump Alignment Tools, Pump Alignment Laser

Pump Alignment refers to adjusting the relative positions of a pump to its driver (typically an electric motor or turbine) to ensure their rotational centers are collinear at operating conditions. Proper alignment is critical for efficient operation, minimizing wear and tear, and prolonging the lifespan of the equipment.

Pump Alignment Tools range from essential hand tools to advanced precision instruments. They include:

- Straight Edge and Feeler Gauges: Basic visual and tactile check tools are suitable for initial rough alignment.

- Reverse Dial Indicators: Precision instruments that measure angular and parallel misalignment between the pump and motor shafts. They are versatile but require manual calculations and adjustments.

- Laser Alignment Tools: These represent the cutting edge in alignment technology, offering high accuracy, speed, and ease of use. Laser systems project a beam detected by sensors, providing real-time feedback on alignment status. They are particularly effective for complex alignments and are indispensable in maintaining high operational standards.

Pump alignment laser technology stands out for its precision and user-friendliness. Laser aligners use a laser beam and a set of detectors to measure the alignment of the pump and motor shafts accurately. This method simplifies alignment by providing instant feedback and detailed instructions for precision alignment. The key advantages include:

- Quick setup and measurement.

- High accuracy and repeatability.

- Minimal user error due to digital readouts and guidance.

- Ability to store and track alignment data over time for maintenance records.

How Do You Fix Misalignment in a Pump?

After you measure pump misalignment, there are a series of steps you should take to correct the error.

Fixing misalignment involves adjusting the position of the pump or motor until the shafts are correctly aligned. Once you have conducted your initial measurements, the process typically follows these steps:

- Loosen the motor mounts: Start by loosening the bolts on the motor mounts to allow for adjustment.

- Adjust position: Adjust the motor’s position based on the misalignment measurements. This might involve shifting it sideways, forward/backward, or changing its height by adding or removing shims under the motor feet.

- Re-tighten and re-check: After making adjustments, re-tighten the motor mounts and re-check the alignment using your chosen tool. This process ensures the alignment is precise.

- Fine-tune: For minor adjustments, use jack screws or similar tools to fine-tune the motor’s position.

- Verify alignment: Conduct a final check to ensure everything is correctly aligned once the alignment is within acceptable limits. Verify that all components are securely fastened.

Implementing proper pump alignment using precision tools, such as laser alignment tools like Pruftechnik’s, enhance the efficiency and reliability of pump systems. This significantly reduces maintenance costs and downtime. Regular checks and maintenance also ensure the longevity of equipment and optimal operational performance.

How Often Should Pump Alignment Be Checked?

There are several factors to consider when determining how frequently pump alignment should be checked., These include the pump’s operating environment, usage intensity, and the critical nature of its function.

You can follow these general guidelines to ensure optimal performance and longevity of your equipment:

- Initial alignment: Always perform alignment when installing a new pump or after significant maintenance on existing equipment.

- Periodic checks: Ensuring alignment at least once a year is recommended for most industrial applications. However, in environments with high vibration, thermal expansion, or where pumps operate continuously under heavy loads, more frequent checks (e.g., two or three times annually) may be necessary.

- After significant events: Check alignment after any event affecting the pump’s position or condition. This includes significant equipment overhauls, after a seismic event, or if the pump or motor has been moved for any reason.

- Signs of misalignment: Outside of these scheduled checks, monitor for signs of misalignment during operation. Keep an eye out for unusual vibrations, frequent coupling failures, unexpected noises, premature bearing failures, or a decrease in pump performance, which may indicate misalignment.

Vibration analysis and other predictive maintenance techniques can also help determine if a pump Is misaligned, allowing for a more condition-based maintenance schedule.

What Are the Different Types of Pump Alignment?

Pump alignment can be classified into several types, each addressing specific alignment challenges and objectives. The two primary categories are angular and parallel misalignment, or a combination of the two:

- Angular misalignment: This occurs when the centerlines of the pump and motor shafts are at an angle. Even a tiny angular discrepancy can lead to significant wear and tear on bearings and seals, reducing the efficiency and lifespan of the pump system.

- Parallel (offset) misalignment: In this scenario, the shafts are parallel but offset from each other, meaning the centerlines do not coincide. This type of misalignment can cause uneven load distribution and increased stress on the pump and motor.

In general, you will perform one of two types of alignment when fixing angular or parallel misalignment:

- Horizontal Alignment: Adjustments are made to align the shafts within the horizontal plane, often requiring lateral movement of the motor or pump.

- Vertical Alignment: This involves adjusting the vertical position of the motor or pump, typically by adding shims under the machine feet, to align the shafts vertically. Best practice is to solve vertical alignment before working on horizontal alignment. An advanced laser alignment tool like RotAlign Touch can help you do both with a single rotation of the shaft.

Types of Alignment Methods:

- Rim and face method: A traditional method where measurements are taken from the rim of the coupling and its face to identify angular and offset misalignment.

- Reverse dial indicator method: This method uses two dial indicators placed at 180 degrees to each other to measure misalignment, capable of identifying both types of misalignment simultaneously. However, this method requires significant experience to perform.

- Laser alignment: The most advanced and accurate method, laser alignment uses laser beams and detectors to precisely measure and correct angular and parallel misalignments.

Each type of pump alignment and method has its application, advantages, and limitations. Choosing the right type and method depends on the specific requirements of the pump system, including the precision needed, the environment in which the pump operates, and the resources available for maintenance activities.