In the fast-paced and competitive manufacturing industry, maximizing machine efficiency and reliability plays a pivotal role in increasing productivity and reducing unplanned downtime. One crucial but often overlooked aspect of machine maintenance is sheave alignment.

Sheaves, which are grooved wheels for use with belts or ropes, are indispensable components in numerous manufacturing processes. That’s why proper sheave alignment is essential for ensuring smooth operations, minimizing equipment wear and tear, and extending the lifecycle of valuable assets. Sheave alignment is closely related to belt pulley alignment.

In this article, we’ll discuss what sheaves are, why ensuring proper sheave alignment is critical, and explain how proper alignment tools, like those offered by Pruftechnik, can help your company effortlessly maintain optimal sheave alignment, boosting both productivity and profitability.

What is Sheave Alignment and Why is it Important?

Sheaves are simple yet indispensable components found in a wide range of manufacturing equipment. They consist of a grooved wheel, typically made of metal or high-strength composites, mounted on an axle. These wheels are designed to guide and transmit power through belts, ropes, or cables, providing mechanical advantage in equipment such as conveyor systems, elevators, and assembly lines.

There are three main types of misalignment issues that plague sheaves:

- Horizontal Angle Misalignment: Characterized by misalignment in the horizontal plane.

- Vertical Angle Misalignment: Occurs when alignment deviates in the vertical plane.

- Axial Offset: Representing misalignment along the axis.

Furthermore, you may also encounter combinations of axial offset and either horizontal or vertical misalignment. And remember, correcting one type of sheave misalignment almost always impacts the alignment in other planes.

Proper sheave alignment is crucial for ensuring that the belts or ropes wrapped around them run smoothly and efficiently, minimizing friction and wasted energy. Improperly aligned or tensioned sheaves can reduce the lifespan of belts and cause excessive wear in connected shafts and bearings.

Top 4 Benefits of Sheave Alignment

Sheaves play a pivotal role in flexible belt drives, which represent a significant percentage of all industrial power transmission applications. That’s because these systems are high efficiency, low maintenance, and can be used with variable-speed power transmissions.

Here are just a few of the reasons it’s important to ensure all of your sheaves are properly aligned:

- Enhanced Equipment Performance: Misaligned sheaves can lead to belt slippage, causing reduced power transmission and diminished equipment performance. Precise alignment ensures optimal energy transfer, maximizing equipment efficiency, reliability, and overall productivity.

- Minimized Wear and Tear: Improper sheave alignment can cause excessive friction between the sheave and the belt, resulting in premature wear and tear on both components. This not only increases maintenance costs but also leads to more frequent part replacement, hampering overall productivity.

- Extended Equipment Lifespan: Consistent misalignment can significantly reduce the lifespan of sheaves and associated equipment. By maintaining proper alignment, manufacturers can extend the life of their expensive machinery, ultimately reducing capital expenditures on new equipment.

- Reduced Downtime: Unexpected breakdowns due to misaligned sheaves can lead to costly unplanned downtime. Regularly aligning sheaves helps prevent unscheduled stops and allows manufacturers to maintain planned production schedules.

As with many other maintenance related activities, an ounce of prevention is worth a pound of cure. So, by adopting a proactive approach to sheave alignment, your maintenance team will ensure it stays focused on predictive rather than reactive maintenance, ultimately saving both time and money.

Precision Tools for Pristine Sheave Alignment

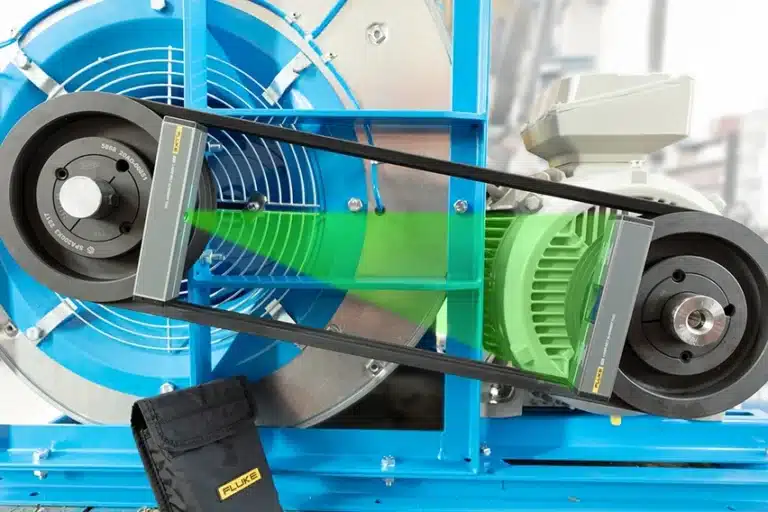

Proper sheave alignment is vital to reducing both excessive wear and the risk of equipment failure. In the past, maintenance teams used a labor-intensive string-and-straightedge method to ensure proper sheave alignment. But modern manufacturing organizations today are more frequently relying on high-tech laser alignment tools, which generate extremely accurate data that can be rapidly analyzed by software.

Pruftechnik’s pioneering laser-based tools have revolutionized the landscape of sheave alignment. Among their array of cutting-edge instruments, their laser pulley alignment system and belt pulley alignment tools stand out as beacons of precision and efficiency.

PULLALIGN: With PULLALIGN, angular, vertical, and horizontal belt pulley misalignment is instantaneously determined via single-laser technology. Its magnet-mounting expedites setup, while its extensive measurement range, up to 10 meters, ensures accuracy even across considerable distances. This system is designed for swift, efficient pulley alignment and practical transport and storage options.

PULLALIGN LITE 2: This tool further simplifies the alignment process. It requires magnet-mounting on one pulley and magnet-mounted targets on the other pulley to yield readings. Its green laser beam ensures optimal visibility in both indoor and outdoor environments. Moreover, height-adjustable targets guarantee precision, accounting for any variation.

The shift towards advanced tools such as these symbolizes a transformative leap from outdated methods that relied on human visual acuity or rudimentary tools like straight edges. Pruftechnik’s tools instead leverage laser precision to swiftly pinpoint even the slightest misalignment, allowing maintenance teams to quickly fix issues before they snowball into major concerns.

Harnessing the Power of Sheave Alignment Tools

Pruftechnik’s commitment to sheave alignment extends beyond talk. Their tools offer tangible solutions that resonate across manufacturing floors, helping maintenance teams optimize machine operations, reduce power consumption, and enhance asset lifespan.

In an industry where every moment counts, embracing laser-based precision tools isn’t just a good idea – it’s necessary for manufacturers that seek to increase their efficiency and bolster their bottom line. And by utilizing the precision of modern alignment tools, your maintenance team can be on the fast track to increasing operational efficiency, equipment longevity, and overall productivity.