In the competitive landscape of industrial machinery maintenance, the role of shaft and coupling alignment is often understated yet crucial. This process, pivotal in sectors such as oil & gas and discrete manufacturing, is the linchpin of machine efficiency and longevity. But what is coupling alignment, and why is it a cornerstone in the world of machinery maintenance?

What is Coupling Alignment?

Coupling alignment is a common name for the critical mechanical process involving the precise adjustment of the axes of interconnected shafts. This process ensures that the shafts are precisely aligned, facilitating optimal power transmission and reducing mechanical stress. In essence, it’s about aligning the centerlines of the coupled shafts so that they form a colinear-axis line during operation.

This alignment is more than just a mechanical adjustment; it’s a safeguard against a range of operational issues. When shafts are misaligned, the resulting mechanical strain can lead to increased wear and tear, excessive vibration, bearing damage, elevated noise levels, and even coupling failure. These issues not only impair the efficiency of the machinery and increase power consumption, but also significantly shorten asset lifespan.

In industries where machinery is the backbone of operations, such as in manufacturing or energy production, coupling alignment takes on a heightened significance. Precision alignment is not just about ensuring smooth operation; it’s about maintaining the integrity and reliability of critical rotating assets. The repercussions of neglecting this crucial maintenance task can be severe, ranging from reduced operational efficiency to catastrophic machinery failures, which can have far-reaching consequences in terms of safety and financial loss.

Importance of Coupling Alignment

Misalignment at couplings can often go unnoticed, but it’s a very destructive force. It can cause excessive vibration, leading to fatigue in machinery parts, increased noise levels, and escalated energy consumption.

The repercussions of ignoring coupling alignment can range from frequent maintenance downtimes to catastrophic machinery failures. For industries relying on continuous and efficient machinery operation, ensuring precise alignment isn’t just a maintenance task—it’s a critical operational necessity.

Understanding Shaft and Coupling Alignment

Shaft alignment and coupling alignment, though often used interchangeably, focus on different aspects of the alignment. Shaft alignment concerns aligning the rotational axes of shafts; this is the true goal of coupled machines. Meanwhile, coupling alignment is about the precise positioning of the coupling that joins these shafts.

Often, the coupling does not precisely represent the axis of rotation. Suppose only the coupling is aligned to its other half. In that case, any offset to the axis of rotation results in misalignment, which is crucial for the harmonious operation of machinery, ensuring minimal stress on mechanical components and optimal power transmission. The term coupling alignment, to the novice, is still often used to describe any alignment.

Different Methods of Coupling Alignment

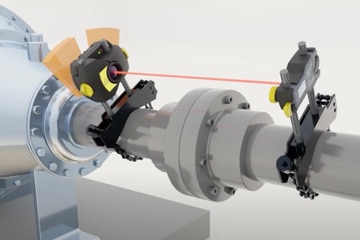

Historically, engineers relied on rudimentary tools like straightedges, dial indicators, and feeler gauges for alignment. These methods, although fundamental, lacked precision and were time-consuming. The advent of laser coupling alignment marked a significant advancement in this field. It brought forth unparalleled accuracy, proper alignment of the axis of rotation, reduced alignment time, and minimized human error. This technology has become a game-changer, especially in industries where precision is non-negotiable.

Step-by-Step Coupling Alignment Procedure

A comprehensive alignment procedure involves several critical steps:

- Preparation: Inspect and clean the coupling area and machinery mounting surfaces.

- Pre-Alignment: Use visual inspection or basic tools to achieve a preliminary alignment.

- Precise Alignment: Employ advanced tools like laser aligners to achieve precise alignment.

- Verification: Conduct post-alignment checks to ensure the alignment is within the specified tolerance.

Each step, performed with meticulous attention to detail, ensures the longevity and efficiency of the machinery.

Coupling Alignment Tolerance: What You Need to Know

Alignment tolerances are not universal; they vary depending on machinery type, coupling type, and operational requirements such as rotational speed. Understanding and adhering to these tolerances is critical. Exceeding these tolerances can lead to increased mechanical stress and operational inefficiencies. That’s why engineers must familiarize themselves with the tolerance standards specific to their machinery and industry.

Laser Shaft Alignment: An Overview

Laser shaft alignment uses a laser beam and sensor to provide a highly accurate and efficient means of alignment. This method is particularly advantageous in complex alignments where traditional methods fall short. The precision of laser alignment minimizes the risk of re-alignment, thereby saving time and resources in the long run.

Best Practices in Coupling Alignment Techniques

Adopting best practices in coupling alignment is vital for maintaining machinery health. These include:

- Regularly training and developing the skills of maintenance personnel.

- Adopting the latest alignment technologies.

- Emphasizing routine maintenance schedules and record-keeping.

- Maintaining compliance with industry standards and manufacturer recommendations.

Implementing these practices ensures that machinery operates at its peak efficiency, reducing unplanned downtime and extending equipment life.

Advanced Topics in Coupling Alignment

Diving deeper, there are some advanced aspects of coupling alignment that reliability engineers should be aware of. These include thermal growth of machinery components, soft foot conditions, and the use of pre-cut precision shims for alignment correction. Understanding these advanced concepts can significantly enhance the effectiveness of alignment procedures.

Effective coupling alignment is a critical element of machinery maintenance, impacting operational efficiency, safety, and cost. With the right approach, knowledge, and tools, such as those provided by Pruftechnik, maintenance and reliability engineers can ensure optimal machinery performance.

Speak to a Specialist

To learn more about our comprehensive alignment solutions and how they can benefit your operations, speak to a specialist at Pruftechnik today. Our expertise in advanced alignment technologies can help you achieve unparalleled machinery efficiency and reliability.