Roosevelt Paper, a paper converter and distributor founded 87 years ago in Philadelphia, maintains long-held traditions behind its paper, providing fast, reliable deliveries and offering pricing that gives its customers a competitive edge. From customer savings to quality assurance and innovation, Roosevelt Paper is devoted to a culture of commitment. The company makes it a priority to invest in state-of-the-art machinery to continue saving its customers time and money while providing flexibility and customization.

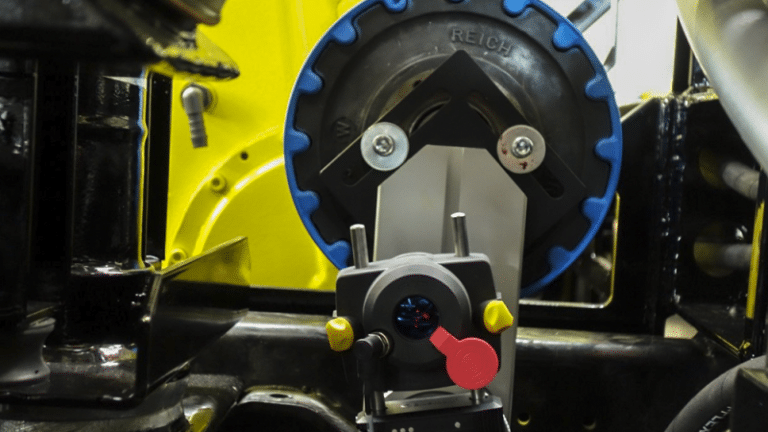

Roosevelt Paper saves time and money by using a gyroscopic alignment service to align its machines during preliminary installations and routine shutdowns to ensure proper alignment throughout the lifetime of the machine. The technology is known as PARALIGN and the service is provided by Fluke Reliability’s alignment team for all three of Roosevelt’s plants in Illinois, Kentucky, and New Jersey. Across these three locations, Roosevelt Paper houses eight sheeter machines and a handful of rewinders.

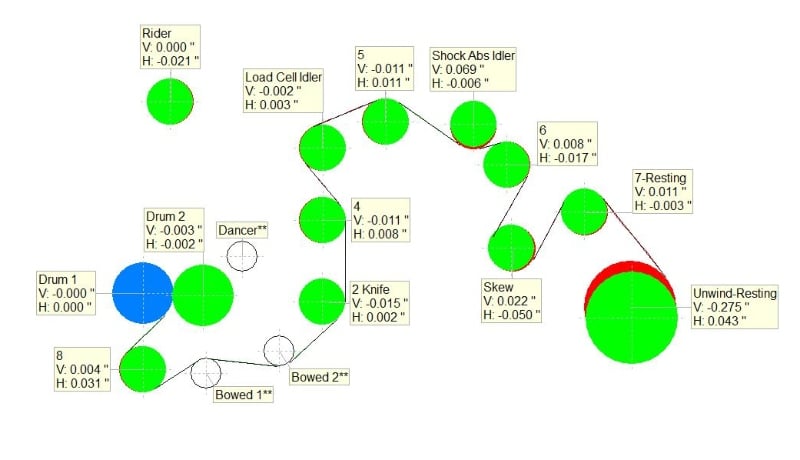

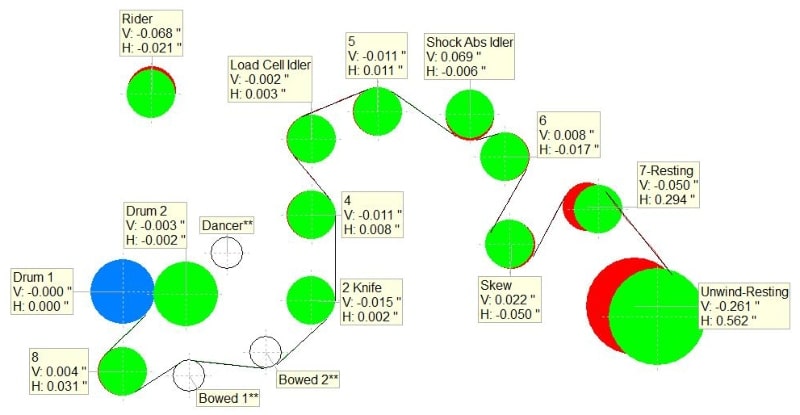

During Fluke Reliability’s recent visit to Alsip, IL, the team measured a Rewinder containing 13 rolls in 20 minutes. Adding the initial set-up time of roughly 30 minutes to the time it took to make adjustments to the machine, Fluke Reliability’s team completed the scope of work to align the machine in less than five hours. During this time, the Fluke service team also completed shaft alignments on two separate motor to roll configurations. This particular project was a new machine installation. Upon initial start-up, the rewinder ran flawlessly. The results of the project follow.

Step by step new machine alignment: Rewinder

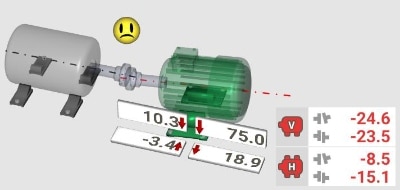

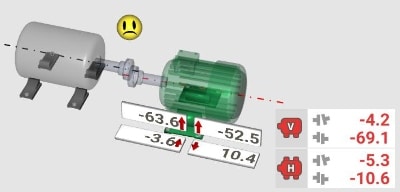

Front Motor Initial

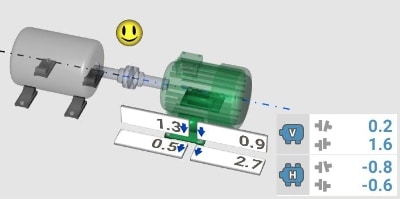

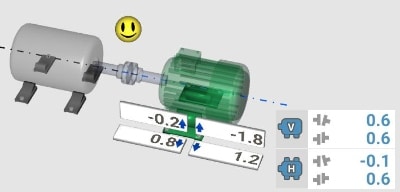

Front Motor Final

Rear Motor Initial

Rear Motor Final

Initial PARALIGN Measurements

Final PARALIGN Measurements