Shaft alignment is key to keeping rotating machines like motors, pumps, gearboxes, and turbines running smoothly. Proper machine alignment means that the rotational centers of two or more shafts are co-linear when the machine is running under normal conditions. Shaft misalignment, or when two or more shafts are not properly aligned, is one of the top causes of failure in rotating machinery, accounting for anywhere from 30 to 50% of failures. However, there are many different types of shaft misalignment.

When shafts are misaligned, this adds unnecessary strain to a piece of equipment, causing premature bearing wear, seal deterioration, and coupling destruction. Over time, this premature wear and tear on the equipment can lead to early or unexpected failure, throwing a wrench into production schedules. Keeping machinery precisely aligned can extend the life of the equipment and keep operating costs low.

In the past, identifying and fixing the different types of shaft misalignment required a highly experienced expert. Today, more and more organizations are using modern laser shaft alignment tools to quickly discover misalignments and fix them easily.

The Causes of Shaft Misalignment

Shaft misalignments are a leading cause of failure for rotating equipment, including critical production assets. It’s important to keep in mind that alignment isn’t a “set-it-and-forget-it” task. Misalignment can happen for many different reasons throughout the life of the machine—from incorrect installation to thermal expansion and settling over time.

Some of the most common underlying causes of misalignment include:

- Human error, like incomplete or poor-quality alignment measurements or inaccurate assembly

- Soft foot triggered by a baseplate settling

- Pipe strain

- Thermal expansion

- Shaft distortion

Five Types of Shaft Misalignment

1. Parallel Misalignment

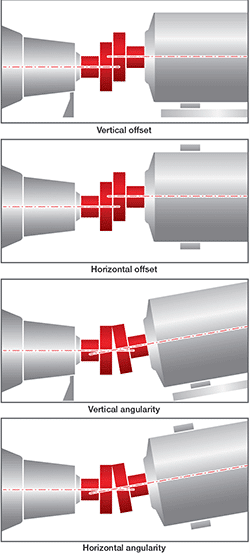

Parallel misalignment occurs when the centerlines of two shafts are parallel to one another, but not in the same plane (offset). Parallel misalignment can be horizontal, vertical, or both.

2. Vertical Angle Misalignment

Vertical angle misalignment is a type of angular misalignment where the centerlines of two shafts intersect at an angle in the vertical plane, rather than being co-linear.

3. Horizontal Angle Misalignment

Horizontal angle misalignment is a type of angular misalignment where the centerlines of two connected shafts intersect at an angle in the horizontal plane, rather than being co-linear.

4. Combined Vertical Angle and Offset

This type of misalignment is the combination of both an offset (parallel misalignment) and a vertical angle misalignment.

5. Combined Horizontal Angle and Offset

This type of misalignment is the combination of both an offset (parallel misalignment) and a horizontal angle misalignment.

Diagnosing and Correcting the Different Types of Shaft Misalignment in Rotating Machines

To keep your operations running smoothly, it’s important to check the alignment of your motor-driven assets on a regular basis, not just during installation. However, the symptoms of shaft misalignment are not always obvious in a visual inspection, and precise alignment is especially challenging without the right tools. The following are a few different tools and techniques you can use to accurately diagnose and correct shaft alignment problems:

A straight edge is a simple tool for technicians to gauge alignment, along with their own visual inspection. However, this only works for discerning visible offsets.

A dial meter is a better option for getting more accurate measurements, but dial meters typically require a highly trained professional technician with the time to take careful measurements.

A laser alignment system is a valuable tool when you need accuracy and precision, but don’t have the necessary technical depth on your team. Laser shaft alignment tools are easy to use, even without a specialized background. To use a laser shaft alignment tool, simply mount your laser sensor onto one shaft, and attach the laser emitter to the other. The laser emitter sends a laser beam to the sensor to check whether the two shafts have a common rotation line. The tool takes the measurements and makes the calculations for you, and then sends that information to an intuitive dashboard that visually guides the user through the alignment process.

Vibration monitoring and analysis is another way you can identify misalignment by continuously monitoring equipment for increases in vibration that can indicate potential misalignment. A vibration analyst can use this vibration data to diagnose and correct the fault.

Thermography is another method that can help detect alignment issues early by identifying hot spot abnormalities. Misalignment might cause an increase in friction within machinery, leading to an increase in temperature. A thermal imager detects and measures an asset’s infrared energy and changes the infrared data into an electronic image showing its surface temperature.

Finally, oil analysis can identify an abnormal condition or parameter and the root cause before the failure further develops. Because oil analysis can be complicated, many organizations use specialized companies to do this for them.