ShaftAlign Touch offers the precision, cloud capabilities, and other benefits of advanced laser shaft alignment in a rugged, user-friendly tool. But the most unique of its many features may be just how adaptive it is.

Adaptive Alignment is a combination of technologies enabling even novice users to consistently and accurately align assets. Single-laser technology is a vital hardware component of Adaptive Alignment, while Active Situational Intelligence (ASI) is a critical element of the software side. Together, they differentiate Prüftechnik from all other laser shaft alignment systems on the market today.

Facilities that could not justify spending the time and training on laser shaft alignment can benefit from the ShaftAlign Touch features. When machines are aligned correctly, they use less energy and don’t require frequent replacement of bearings and seals.

There are three specific ways in which ShaftAlign Touch is adaptable.

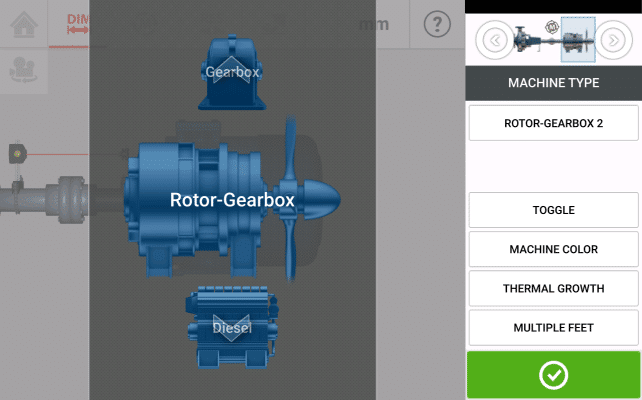

Adapting to the asset

The ShaftAlign Touch can be used to identify and handle horizontal, vertical, and angular alignment challenges. The integrated RFID machine identification reader ensures that users can find the correct machine and see its alignment history. The Machine Flip feature allows technicians to align machines are obstructed. And measurements can be taken no matter how severe the misalignment.

Adapting to the situation

Single-laser technology offers quick setup and adjustment, saving time and frustration. No pre-alignment or rough alignment is needed. A large touchscreen, straightforward workflow, and guided user interface make the tool easy to use. Problem-solving with ASI software delivers corrective feedback to users.

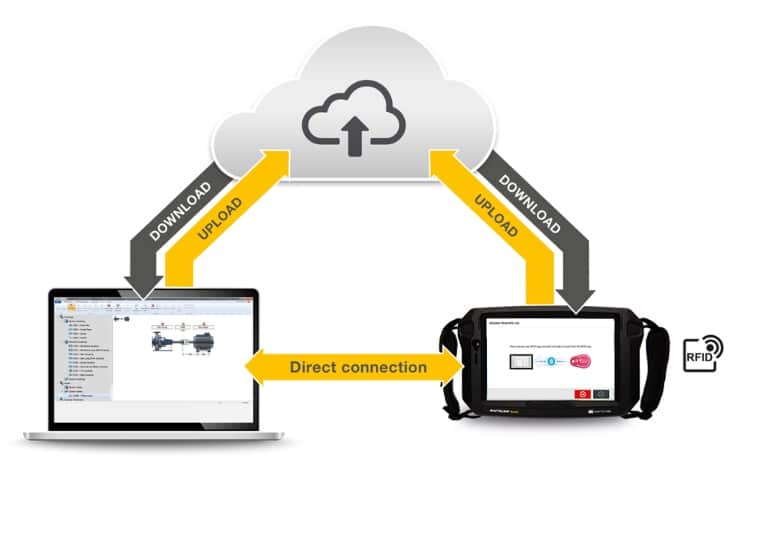

Adapting to the team

The ShaftAlign Touch empowers every team member, regardless of experience level, to align almost any asset with precision and speed. Low-quality measurements, whether caused by the user or backlash, are exposed and can be filtered out.

This capability provides users with reliable, repeatable results—no matter who on the team is performing the measurement. Also, ARC 4.0 software sends measurements to the cloud in real time, making it possible to confer and collaborate with colleagues or consultants anywhere in the world. The ShaftAlign Touch is the only entry-level laser alignment system with cloud connectivity.

With the new ShaftAlign Touch, maintenance teams can affordably switch from their decades-old legacy tools to the latest premium digital system without budgeting extra time or money for training.

When even novice users can succeed at completing most alignment jobs, machines will run better and longer. Downtime and maintenance spending will show a downward trend.