It looks like we’ve struck a nerve in the laser shaft alignment market with our announcement of Adaptive Alignment systems.

All of a sudden, various forms of the word “adaptable” have been popping up on social media posts about laser alignment systems that do not possess Adaptive Alignment technology.

We at PRUFTECHNIK are glad to see others admit that adaptability is indeed a valuable must-have in laser alignment systems. We welcome them to the conversation.

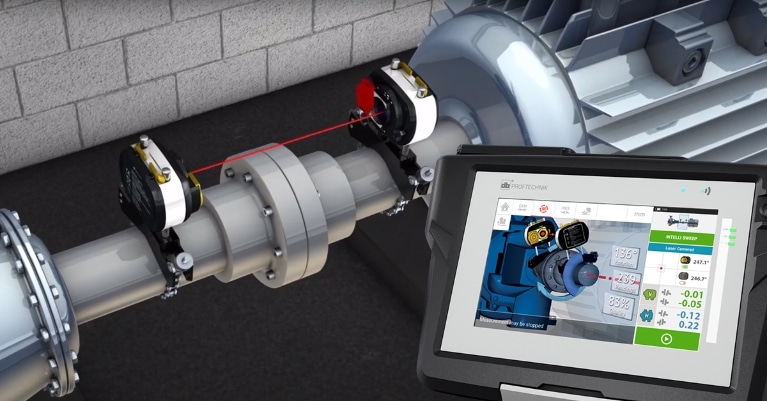

Of course, it’s easy to use words like “adaptable” in a social media post. The hard part is actually engineering Adaptive Alignment capabilities into a laser alignment system. By that, we mean features that make adaptability happen during an alignment job, – such as single-laser technology and Active Situational Intelligence (see our white paper here).

Breakthrough engineering work is what separates innovators from imitators. PRUFTECHNIK—the undisputed world leader in laser shaft alignment—has continued to revolutionize with patented inventions that are realized in our Adaptive Alignment solutions.

But when many vendors freely use the word “adaptable,” how can maintenance practitioners separate true Adaptive Alignment systems that deliver higher precision with faster job completion from imitators that still operate in a basic way?

By asking, “How.” How do systems claiming to be adaptable actually deliver Adaptive Alignment benefits? Here are some specific questions:

- Does the system include single-laser technology?

If not, it cannot adapt to situations such as large misalignments. Common workarounds that add time and potentially compromise precision include recommendations to do “rough alignment” or “pre-alignment” before tackling the rest of the job. - Does the system deliver real-time feedback during, as opposed to after, the measurement?

If not, it is not adapting to user needs. - Does the system automatically detect and eliminate coupling backlash as measurements are taken?

Basic systems leave it up to the user to make sure backlash is not influencing the measurement. - Does the system include the ability to share measurements over the cloud to support team collaboration?

If not, the technician is on his own at the machine, and the system is not adapting to teams that need collaborative capabilities - Is the system automatically aware of and can handle uncoupled shafts?

A common installation-time need, Uncoupled Shaft Awareness, eliminates the manual positioning exercises commonly needed with basic alignment systems.

There are other questions that practitioners could and should ask before investing in a laser shaft alignment system. If you want to know what they are, don’t hesitate to contact us.

In the meantime, we at PRUFTECHNIK, a division of Fluke Reliability, welcome the marketplace validation of the value of Adaptive Alignment.

As with any advance that is imitated, sly usage of similar terms can make it difficult for users to separate the innovation from the imitation. We encourage maintenance leaders to learn about the key ingredients of Adaptive Alignment – which they can do here.

In the end, it’s not merely a battle over the meaning of the word “adaptable.” For maintenance teams charged with keeping their machines at peak performance while operating at peak efficiency themselves, Adaptive Alignment is one key to a successful future.

If you’d like to learn more about our Adaptive Alignment systems, we suggest digging into the information on this page or getting in touch with your PRUFTECHNIK sales representative today!