A key benefit of online condition monitoring tools for rotating equipment is the ability to view data from anywhere. For instance, a company with locations in different continents can share vibration analysis and balancing data reports with its field workers and partners throughout the world.

Devices such as the PRUFTECHNIK VIBGUARD, VIBRONET Signalmaster, and VIBSCANNER 2 employ Industrial Internet of Things (IIoT) capabilities that allow collected data to be pushed to digital dashboards, HMI systems, and email notifications. Plant managers, engineers, vibration analysts, and technicians can check machine health from their PC or mobile device at home or in the office. Real-time data helps teams make decisions wherever they are located.

It’s all about the software

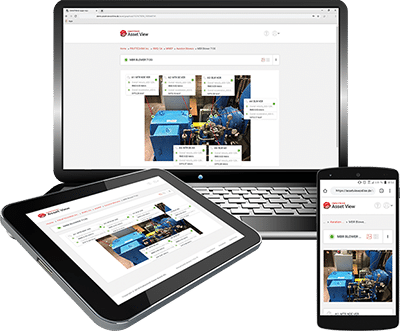

Several PRUFTECHNIK condition monitoring systems feature OMNITREND Asset View software. OMNITREND Asset View enables data to be sent via the IIoT interface MQTT for global access and remote viewing. This platform is easy to use and configure; it features real asset images and setting measurement points with drag and drop capabilities. You can also reset alarm modes remotely.

The OMNITREND Center, another software application in these devices, also allows data to be shared remotely. After measurement data is collected, it can be downloaded onto a PC and emailed to a maintenance specialist.

With remote access to machine condition data, your team has the flexibility it needs to make better maintenance decisions, avoid unscheduled downtime, and save time and money.

Learn more about PRUFTECHNIK condition monitoring tools and software (pruftechnik.com)