Among the most challenging machinery alignment tasks you might face is aligning a Cardan shaft—named after 16th-century Italian polymath Gerolamo Cardano, who invented it along with other machine mechanisms.

Cardan shafts are essentially couplings. Their purpose is to accommodate a horizontal or vertical offset between a driven shaft and a driving shaft—most commonly a motor and a gearbox.

The Cardan shaft is the input shaft to the gearbox—versus the slower output shaft of the gearbox. Together, the rotational speed of both shafts connecting the motor to the gearbox via the Cardan shaft is the same.

Angular misalignment can increase the strain on joints and bearings and lead to a Cardan shaft becoming damaged or destroyed. Angular misalignment also often leads to increased vibration, which can cause uneven rotation during operation and, ultimately, shortened asset life.

Fortunately, with adaptive alignment systems from PRUFTECHNIK, it is quick and easy to measure the parallelism of two shafts connected to a Cardan shaft.

No removal is required, and measurements are much easier

The usual method of aligning these assets is to take the Cardan shaft out to align it, which requires dismantling and removing the Cardan shaft. This process can be cumbersome and time-consuming, and sometimes even requires a hoist or a crane.

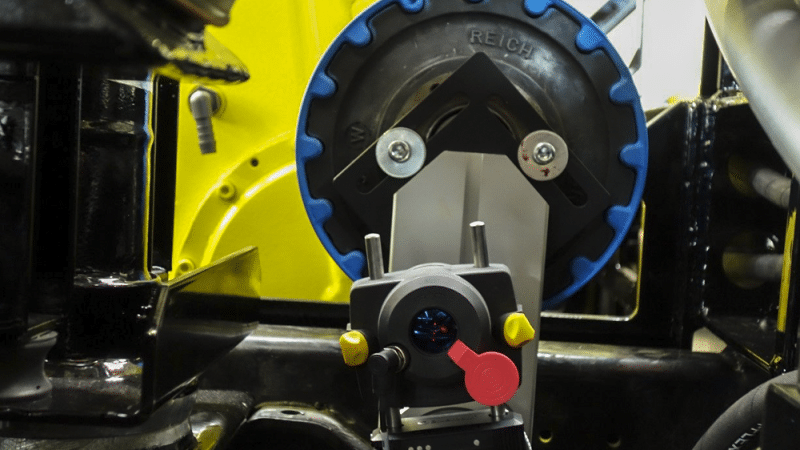

But with adaptive alignment, it is possible to perform measurements with the Cardan shaft in place by using a specially designed rotating arm bracket fixture. This innovation is called in-situ Cardan shaft alignment. With no removal required, measurements are obtained much more easily and without the need for lengthy downtime.

Cardan shafts often exist in tight spaces, which can be challenging to navigate when using standard alignment procedures. But with adaptive alignment in-situ shaft measurement, tight spaces are no problem at all.

Two specific features of adaptive alignment, single-laser technology and Active Situational Intelligence (ASI), make it easier to handle difficult alignment situations, such as tight spaces, while also increasing both measurement speed and accuracy.

Measurements are reliable and precise—accurate to a hundredth of a millimeter. Successfully aligning a Cardan shaft requires a level of precision most easily achieved using single laser technology. Determining the parallelism of two shafts connected by a Cardan shaft is much quicker and easier, thanks to adaptive alignment.