By Eric Elder

Thermal growth is the expansion of matter caused by an increase in temperature. In rotating equipment, this happens while the machine is in use since heat builds when individual parts inside the asset move and interact with each other.

Factors such as friction cause the temperature of the equipment to rise. The increase in heat causes metal to expand, resulting in thermal growth, which, if not accounted for in the alignment process, can cause misalignments. Even small amounts of thermal growth can cause major alignment issues and a resulting cascade of problems in rotating equipment.

In this article, you’ll learn the causes of thermal growth, how to reduce it, and why laser alignment can help you keep thermal growth under control, just as it did for a leading turbine manufacturer.

How Do You Calculate Thermal Growth?

In order to calculate the thermal growth of rotating equipment, you need to know three key pieces of information.

First, you need to know the differential temperature, T, of the material. This is the difference in temperature between the material when the rotating equipment is cold at rest and the highest temperature the equipment reaches while it’s in use.

Example: The temperature of the machine when it’s not in use is 70 °F. The equipment reaches 130 °F when it is in use. In this case, T = 60 °F.

Next, you need to know the linear dimension of the material being calculated. The linear dimension is the length of the material in inches (in).

Example: The rotating shaft is 10 inches long. In this case, L = 10 in.

Finally, you need to know the coefficient of linear thermal expansion for the material in question. This is a constant that depends on the material being used. Here is a chart with the coefficient of linear thermal expansion for common types of metal used in rotating equipment:

Example: The shaft in question is made of stainless steel. The coefficient is .0000074.

Multiply the three numbers together to find the thermal expansion for the equipment.

T x L x C = Thermal growth in inches

Example: 60 °F x 10 in x .0000074 = 0.00444. The shaft will grow .00444 inches.

Causes of Thermal Growth

Thermal growth is caused by the increased operating temperature of rotating equipment when in use. The temperature increase can have many causes, some of which are normal and not a cause for alarm.

Even with proper lubrication, friction caused by moving parts in the machine can lead to temperature increases. Electrical components like motors and transformers can generate heat due to resistance in their windings and circuits, and processes such as energy conversion from electrical energy into mechanical energy can also cause an increase in temperature.

It’s important to track how much thermal growth an asset experiences on a regular basis to establish a baseline. When machines generate more heat than normal, it can be a sign that your rotating equipment may have underlying issues.

How to Reduce Thermal Growth

Thermal growth is a natural result of using rotating equipment. However, if temperatures are rising beyond the normal safe operating temperatures expected, it can point to a problem that needs to be addressed with machine maintenance.

Depending on the type of equipment, here are a few steps that can keep thermal growth in check:

- Lubrication: Proper lubrication can help reduce friction, which causes the temperature in rotating equipment to increase.

- Ventilation: Check vents and fans to make sure they are working properly and aren’t blocked.

- Electrical issues: Check that all electrical components are operating correctly. Voltage irregularities, poor connections, and faulty wiring can all cause overheating.

- Component damage: Damaged components like bearings or seals can cause temperature increases due to higher friction.

- Shaft alignment: Making sure rotating equipment is properly aligned can also reduce friction and heat caused by excess strain on components.

How Laser Alignment Tools Help Reduce Excess Thermal Growth

Shaft alignment can help reduce the negative effects of thermal growth. The alignment process itself also has to take thermal growth into consideration.

The example presented above is simplified to explain thermal growth. In reality, accounting for thermal growth in rotating equipment can be much more complicated.

Rotating equipment is often made up of more than one type of material. Equipment may also experience uneven heating across the entire machine, and thermal growth isn’t limited to the shaft itself. For example, the front of a machine may have a fan that helps it cool, so it doesn’t reach as high of temperatures as the back of the machine does. And to make matters even more complicated, thermal expansion occurs in all directions, not just one.

All of these factors make traditional rotating equipment alignment nearly impossible when taking thermal growth into consideration. However, laser alignment methods automatically account for thermal growth and offer a modern alternative.

Laser alignment works by using a transmitter and a detector. These are mounted on the machine above the shafts while the rotating equipment is cold. Once the devices are mounted, the equipment is turned on. The device logs the changes that occur between both sides of the shaft as the temperature continues rising.

Once the temperature stabilizes at its highest point, the data can be used to perform alignment. It takes into account both vertical and horizontal thermal growth that occurs while the equipment is running.

Accounting for thermal growth during the alignment process ensures rotating equipment remains properly aligned while in use. Without taking this key step, thermal growth will lead to misalignment.

Case Study: Leading Turbine Manufacturer Keeps Thermal Growth in Check

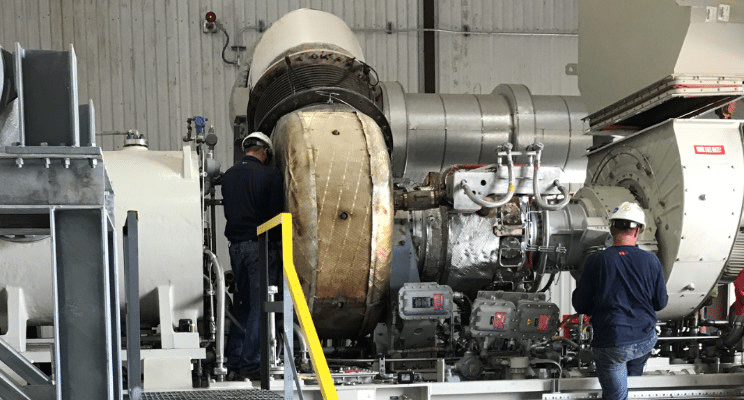

When it comes to high-speed machines such as turbines, thermal growth is something that companies almost always must monitor.

A PRÜFTECHNIK services team helped a leading manufacturer of industrial gas turbines for the global power generation market to precisely measure the thermal growth of a turbine unit using the ROTALIGN® touch.

With thousands of units amassing billions of operating hours, this manufacturer understands the importance of precision alignment. That’s why it called upon PRUFTECHNIK, as the global leader in laser shaft alignment, to handle the measurement.

What is thermal growth? It is the expansion of a machine as its temperature increases due to regular operation. Thermal targeting properly aligns the shafts when they heat up to operating temperatures.

Gas turbines produce a large amount of heat and thus are subject to significant amounts of thermal growth. Failure to account for the thermal expansion can result in misaligned shafts that produce unwanted vibrations and damage to bearings. These side effects ultimately reduce the lifetime of a machine and result in machine downtime.

To prevent this, the turbine manufacturer uses the latest technology available to account for thermal growth and to align the shafts of its turbines properly.

Figure 1: An example of a thermal growth trend.

The gas turbine manufacturer has chosen the PRÜFTECHNIK alignment services and advanced ROTALIGN® series alignment platform to fine-tune its gas turbines for best performance.

ROTALIGN touch features a laser-based system that includes a transmitter and a detector. These are mounted to the gas turbine and the driven machine at a location just above the shafts. Once the devices are stably mounted, the turbine revs up to operational speeds.

As the temperature of the turbine grows, the device logs data that shows the relationship of movement between both the driving and driven machines.

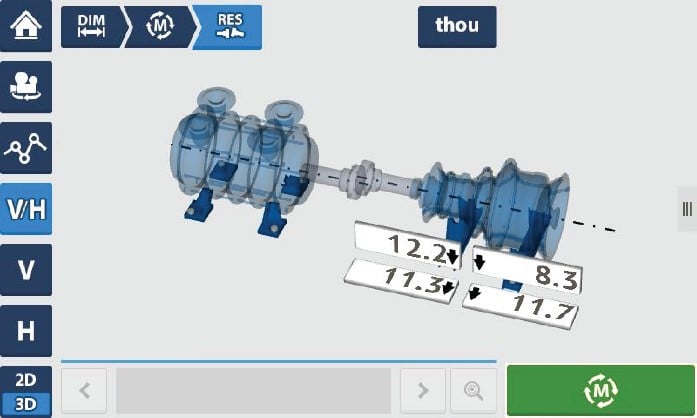

Figure 2: An example of thermal growth results.

Data logging is complete once the temperature of the machine has stabilized. The ROTALIGN® series alignment platform is then capable of analyzing the data automatically to determine the horizontal and vertical changes necessary at the mounting locations of the gas turbine, as seen in Figure 2.

These changes allow for the machine to be correctly aligned when it is running at operational temperatures. The gas turbine manufacturer is taking advantage of this technology to gear its turbines for increased reliability and optimal performance. With PRUFTECHNIK products and services, the thermal growth of its machines is in check.

Eric Elder is PRUFTECHNIK Service Manager for the Americas at Fluke Reliability.