Peak motor performance is pivotal in today’s industrial maintenance environment, which means that motor alignment is also now more crucial than ever before. Proper motor alignment not only ensures efficient operation but also significantly extends equipment lifespan.

This article explains the finer details of motor alignment, focusing on the pivotal role of advanced technologies like laser alignment. We’ll also discuss the importance of choosing the shaft alignment tool that’s right for your plant.

Why Motor Alignment is Important

Motor alignment is the process of adjusting the relative positions of a motor and the driven equipment to ensure that the rotational centers of both are aligned. Misalignment can cause various problems, including increased vibration, premature wear of bearings and seals, and even catastrophic equipment failures.

Precision motor alignment is not just a maintenance task; it’s a critical investment in the longevity and efficiency of your machinery.

Laser Shaft Alignment: The Gold Standard in Motor Alignment

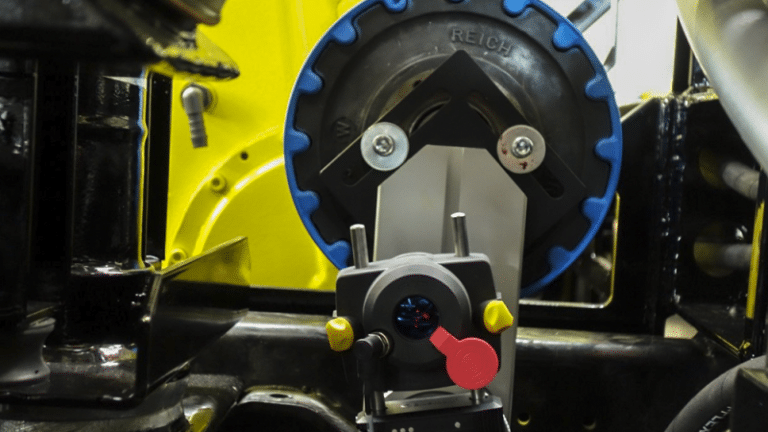

Historically, technicians performed motor alignment with rudimentary tools like straight edges and feeler gauges or dial indicators. While effective to a degree, manual techniques required significant expertise and left room for inaccuracies. However, the advent of laser alignment technology marks a significant leap forward in the field.

The best laser alignment systems provide high precision, ease of use, and repeatability, making them indispensable in modern industrial settings. Laser alignment utilizes laser beams to measure misalignments between the motor and the driven equipment. This method offers several advantages over traditional alignment techniques:

- Reduced maintenance time. Precise laser alignment means significant reductions in the time required to perform maintenance.

- Quick and easy checks. Ease of use allows for more frequent checks and adjustments.

- Ensured accuracy. The best laser alignment tools offer unparalleled precision.

- Enhanced longevity. When motors and equipment are perfectly aligned it minimizes wear and tear and optimizes performance.

However, not all laser alignment tools will be of the same quality or boast the same benefits. There are some features you’ll want to look for when choosing the right motor alignment tool for your plant.

Choosing the Best Motor Alignment Tool

There are a number of shaft alignment tools on the market today, but not all cater to the same standards for precision in industrial environments. When selecting a shaft alignment tool, consider the following:

- Precision: Look for tools that offer high-precision measurements. There’s a big difference between aligning to within tenths of an inch and hundredths or thousandths of an inch. A more accurate measurement means better-performing, longer-lasting machinery.

- Compatibility: Ensure the tool is compatible with the types of motors and equipment in your facility.

- Ease of use: The tool should be intuitive and user-friendly, enabling technicians to perform alignments efficiently.

- Durability: Industrial environments can be harsh. Opt for a robust tool that can withstand the rigors of daily use. If you need an intrinsically safe tool, you’ll also have to find a provider who can offer that option.

Having a highly precise laser alignment tool like the Prüftechnik RotAlign Touch makes machine adjustments a breeze. When making use of precious planned downtime, agility and accuracy is crucial to getting maintenance done in a timely fashion.

The Role of Adaptive Alignment in Motor Maintenance

Adaptive alignment systems represent the latest innovation in motor alignment technology.

These systems are equipped with advanced features such as Active Situational Intelligence (ASI) from Pruftechnik, which automatically adjusts to the alignment challenges present. This technology makes them suitable for a wide range of applications.

Adaptive alignment systems are particularly beneficial in complex alignment scenarios, offering precision and flexibility unmatched by traditional systems.

Starting a Motor Alignment Program

For plant managers and maintenance teams, establishing a motor alignment program should be a priority. Having a plan for regular alignment checks and making sure you have the right equipment on-hand helps keep machines running smoothly and minimizes unplanned downtime.

Your alignment program should include routine alignment inspections, the use of appropriate alignment tools, and training for maintenance personnel.

Investing in high-quality laser alignment systems can result in significant savings in maintenance costs improve overall equipment efficiency, and boost workplace safety.

Conclusion

Motor alignment is a fundamental aspect of industrial maintenance that ensures the efficient and reliable operation of motors and the equipment they drive. The advent of laser alignment and the evolution of adaptive alignment systems have revolutionized the process, offering precision, efficiency, and adaptability.

By choosing the right shaft alignment tool and implementing a comprehensive motor alignment program, plant managers can safeguard their machinery, optimize performance, and achieve substantial cost savings in the long run.

Staying ahead of the latest advancements in motor alignment technology is crucial. Embracing these innovations enhances operational efficiency and contributes to the sustainability of valuable industrial assets.

To learn more about our comprehensive alignment solutions and how they can benefit your operations, speak to a specialist at Prüftechnik today. Our expertise in advanced alignment technologies can help you achieve unparalleled machinery efficiency and reliability.