Do you really need to get your tool recalibrated when everything seems to be running smoothly? Your alignment and condition monitoring instruments are still working properly, and the readings seem fine — what’s the rush? But the reality is that missed calibrations don’t cause immediate consequences. That’s why it’s important to adhere to a regular schedule even when tools are working like normal.

Regular calibrations are like getting an oil change for your car. The vehicle may run just fine for a while, but without regular maintenance, wear and tear gradually builds up under the hood. Your engine loses efficiency, parts wear out faster, and eventually, you’re hit with a costly breakdown. In the same way, condition monitoring and alignment tools that are overdue for calibration slowly drift out of accuracy, which can then snowball into bigger issues.

Therefore, while skipping regular calibration — which is recommended every two years for your tools — may seem like a way to save time and money in the short term, it’s actually a gamble that could lead to unexpected costs, inefficiencies, and equipment failures. Let’s break down the real impact of neglecting calibration for your alignment and condition monitoring instruments and what it could mean for your bottom line.

What Causes Tools to Drift Out of Accuracy

Drift refers to the gradual loss of accuracy in calibration equipment. Even the most reliable alignment and condition monitoring tools will experience drift over time. Several factors contribute to this decrease in precision:

- Normal wear and tear. Just like any other piece of equipment, measurement tools degrade with use which can lead to small but significant shifts in accuracy.

- Environmental factors. Temperature fluctuations, humidity, and exposure to dust or corrosive substances can affect sensitive components

- Physical shocks or mishandling. Tools that experience frequent movement or rough handling are more likely to fall out of calibration. This is especially common in fieldwork, where tools are regularly transported or used in harsh environments.

- Electrical interference. For tools that rely on electronic components, nearby electromagnetic fields or power surges can impact their accuracy.

- Aging components. As with any technology, certain parts of a measurement tool naturally degrade over time, affecting precision.

While everything may appear fine on the surface, gradual shifts in accuracy can continue to worsen, often going unnoticed until they lead to bigger problems.

Reliability and Efficiency: The Hidden Ripple Effect

The accuracy of your alignment tools and condition monitoring instruments directly impacts your operations. When that accuracy starts to drift, even by a small margin, it can have far-reaching effects on your equipment’s performance and operational efficiency. Think of expensive unplanned disruptions, failed compliance tests, and compromised product quality.

Here’s how even small inefficiencies can add up over time:

- Unplanned downtime. Without calibrated tools, critical early warnings of misalignment or performance shifts can go unnoticed. This can result in sudden equipment failure, bringing production to a halt and causing significant downtime. The resulting delays and repairs can disrupt workflows and negatively impact your bottom line.

- Process inefficiencies. When calibration drifts, the data your team relies on may become inaccurate, leading to rework, wasted materials, and inefficient workflows. Condition monitoring tools that miss subtle changes in machine performance exacerbate these inefficiencies, driving up costs and reducing productivity.

- Inconsistent quality. Instruments overdue for calibration can produce inaccurate measurements, leading to variations in product quality. Misaligned machinery or undetected equipment wear can result in rejected batches, higher rework rates, and damage to your brand’s reputation.

- Increased safety risks. Tools that need to be calibrated can give incorrect readings, such as from pressure gauges or vibration monitors, which may lead to unsafe working conditions. In industrial environments, this increases the likelihood of accidents, equipment failure, or even injuries.

- Regulatory non-compliance. Many industries, especially those requiring certification like ISO 9001, mandate regular calibration. Failing to meet these standards can result in fines, legal issues, and loss of certifications.

The time and money spent recalibrating tools are minor compared to the massive consequences and costs that can arise from unreliable devices.

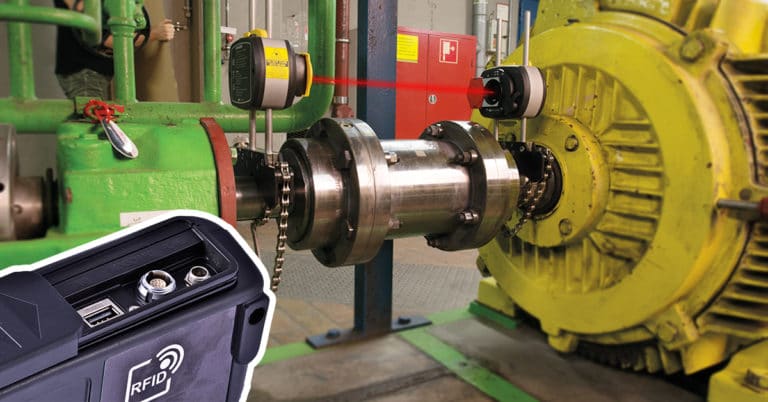

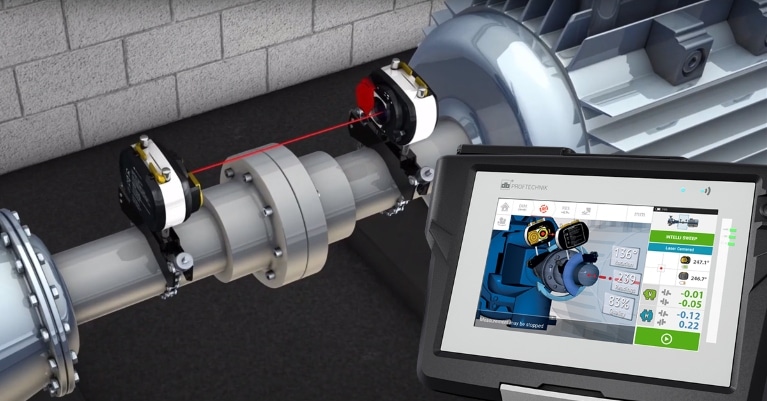

How Prüftechnik Calibration Services Keep Your Tools at Peak Performance

When it’s time for regular calibration, here’s what you can expect when you send your tools to Prüftechnik to be calibrated.

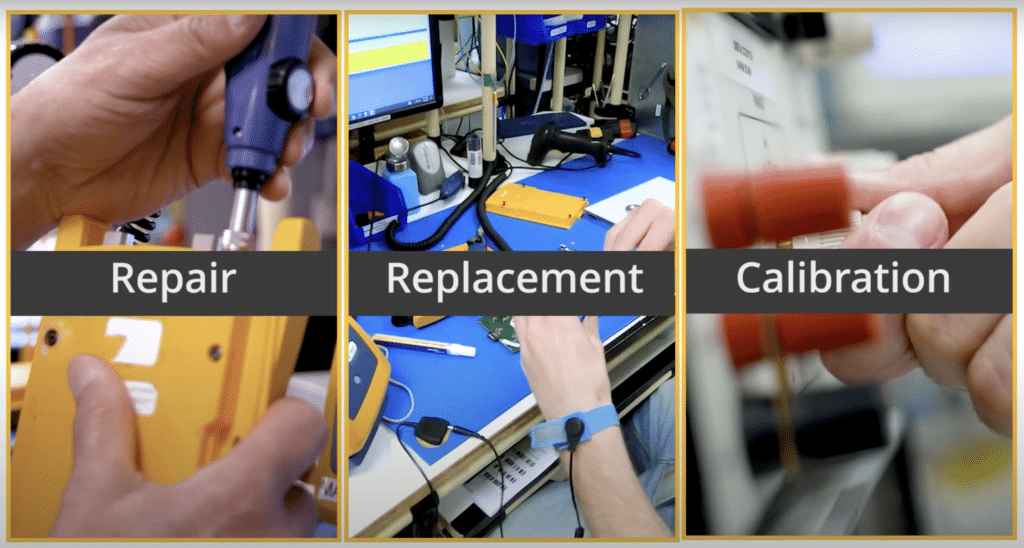

- Expert calibration: Our team of OEM-trained engineers ensures that your tools are recalibrated to precise standards, maintaining the reliability of your equipment.

- System inspection and cleaning: Beyond calibration, we inspect and clean each component to help minimize the risk of equipment failure and extend the lifespan of your tools.

- Preventive repair: We carry out preventive maintenance to identify potential issues early, reducing the chances of unexpected malfunctions.

- Firmware updates: Where applicable, we update your system to the latest firmware, ensuring compatibility with new features and improved performance.

We’ll also issue a new calibration certificate for every device we work on. This can be used to demonstrate compliance with quality requirements like ISO 9001, as our calibration services are traceable to international standards.

Precision Pays Off

In the end, it’s the small effort you put into getting routine calibration for your devices that prevents larger, costly issues from creeping up when you least expect them. After all, much like a car, it’s the regular tune-ups that keep everything moving forward — without the unexpected breakdowns.

Get in touch with Prüftechnik today to schedule your calibration service.