Vibration sensing technology is less than 100 years old. And yet, in that time, it’s become a staple in manufacturing and industrial settings, healthcare, cellphones or tablets, and more. Detecting the direction, severity, and fluctuations of vibration is common in our modern world, even more so in industrial or commercial spaces — where asset downtime can result in production losses or health issues.

Just as with technology over the last century, vibration monitoring sensors have vastly evolved since those early days. Wherein the early part of the previous century, scientists had just developed accelerometers; nowadays people wear them on their arms or in their pockets. And just like in society, if we want to know where we are going, sometimes it’s best to look back.

Pre-computerized Accelerometers

From 1920 through to the early 1940s, vibration sensing technology was non-existent. However, the scientific exploration into vibrations was well underway. The first commercialized accelerometer was a simple yet heavy instrument engineered by B. McCollum and O.S. Peters in 1924. A year later, engineers applied it to architecture, aerospace, earthquake recordings, and other industrial uses — though not in maintenance yet.

While early accelerometers found their uses, the development of smaller and more accurate sensors never waned. Mid-century, the piezoelectric accelerometer came on the market, and even today it’s continuing to revolutionize vibration sensing technology.

Industrial Vibration Detectors

By the 1950s, corporations were creating vibration detection instruments on mass production scales. Early pioneers in vibration technology, such as Bruel and Kjaer (B&K), Columbia Research Labs, or Gulton Manufacturing, evolved accelerometer technology for specific uses in industrial areas.

At the height of World War II, Per V. Brüel and Viggo Kjaer1 created their company (B&K). They developed the world’s first piezoelectric accelerometer, made from Rochelle salt. The concept was simple: By placing an accelerometer against a machine, one could determine the direction, severity, and frequency of vibration, as well as determine when that machine may be closer to a failure.

Post-WWII Vibration Technology

In the sixties, tunable analog filters were added to meters so that users could discriminate between frequencies. Valuable when troubleshooting assets with connected components. B&K also launched their first handheld meter, another world-first, too.

Around this same time, fast Fourier transform (FFT) vibration detection and analysis started increasing (FFT being an algorithm for transforming a time-domain signal into a frequency domain signal). These devices could not only capture but also record data. However, at around 75 pounds, they were just a tad impracticable. For vibration technology to be applicable in everyday maintenance, it had to be easy to use.

The late 80s saw an explosion in microprocessors, both in personal and industrial computing capacities. As tech shrunk, it got more portable. In a 1998 paper titled “Fifty Years Plus of Accelerometer History for Shock and Vibration (1940-1996),” Patrick L. Walter was succinct in his conclusion:

“Since its inception, the accelerometer marketplace has greatly expanded… The current rate of technology advancement in microsensors and microelectronics indicates that future expansion in accelerometer manufacturers and capabilities will occur at an even faster pace than in the past.”

And that was published more than 20 years ago. Since then, vibration monitoring technology has gained traction and evolved even further.

Smaller Vibration Devices, More Data

During the first part of the new millennium, vibration technology continued to shrink in size while providing ever-increasing data capacity. This was around the time Fluke stepped into the fray with their popular Fluke 810 Vibration Spectrum Meter. These meters used an Overall Vibration Spectrum to provide a detailed description and visual representation for vibration severity.

Later iterations of the Fluke 810, and the subsequent 805, could send data to cloud-based software with the push of a button. Connecting data to cloud repositories and vibration analysis software opened the world of vibration maintenance from the hands of the few into the palms of the many. No longer was vibration analysis some expensive expertise; it was democratized. Anyone with any experience level could take vibration readings, send them to software, and prepare vibration analysis for their review.

In the decade since their first vibration product, Fluke has engineered several levels of vibration detection sensors, from handheld meters to the latest in connected sensor technology. They’ve been brought to market by Fluke Reliability, the Industrial Internet of Things arm of Fluke test and measurement tools.

Spectrum vs. Overall Analysis

Spectrum Analysis uses FFT to reconstruct the time domain signal using a series of harmonic sine waves.

Overall Analysis is much simpler, taking the original time-domain signal and assigning one overall vibration value to the data.

Today Leads to the Future

Today’s sensors and the predictive maintenance reality directly lead to the IIoT-enhanced, prescriptive maintenance future. A future where software will inform maintenance teams on when, where, and why to complete maintenance.

Fluke 3563 Analysis Vibration Sensor

Another recent launch by Fluke Reliability is the 3563 Analysis Vibration Sensor. These higher-frequency sensors allow maintenance teams to monitor and gain deeper insights from data. Finding the root cause of the fault helps maintenance teams keep assets more reliable and extends peak operating performance. On top of sensors, the analysis vibration sensor also comes with services from Fluke Reliability experts.

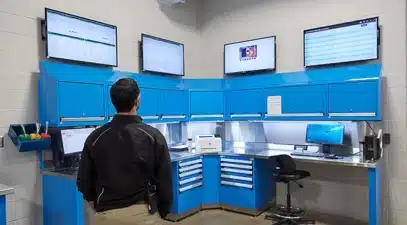

Prüftechnik Vibration Portfolio

Prüftechnik also has deep expertise in predictive maintenance technologies, with solutions like handheld vibration measurement tools, wired sensors, and condition monitoring services. For handheld vibration collection and analysis devices, their VibScanner and VibXpert series are second to none. While those needing more stringent and around-the-clock monitoring can leverage Prüftechnik’s Online Condition Monitoring software and services to ensure uptime.

To learn more about vibration monitoring, please sign up for a chat with one of our knowledgeable staff.

Resources: Walter, Patrick L. “Review: Fifty Years plus of Accelerometer History for Shock and Vibration (1940-1996).” Semantics Scholar. Engineering Department, Texas Christian University, Fort Worth, Texas, December 7, 1998. shorturl.at/aioDI. History of the Piezoelectric Accelerometer. Brüel & Kjær, an HBK Company. Accessed November 17, 2021. shorturl.at/elCGV.