Every machine has its own vibration signature, and changes in a machine’s vibration can indicate potential faults. Different types of vibration sensors mounted on motors and other equipment can detect when and how a machine’s vibration changes. That vibration monitoring data can be analyzed and trended to help maintenance teams plan and prioritize their work.

There are multiple types of vibration sensors available, with options for many applications and budgets.

Types of Vibration Sensors

Piezo Vibration Sensors

Piezoelectric vibration sensors (also called piezo vibration sensors) capture changes in physical parameters or forces. The applied force generates an electrical charge, which is then converted into measurable electrical signals.

Piezo vibration sensors capture highly accurate and dependable data, and they are robust and rugged enough to withstand harsh environments. Those qualities have made an extremely popular choice for industrial vibration sensors. For example, they can handle a wide range of temperatures.

And while piezo vibration sensors’ sensitivity and small size make them ideal for many industrial applications, one drawback is that they can consume more power than some other types of vibration sensors.

Accelerometer Vibration Sensors

Accelerometer vibration sensors are another extremely common type of vibration sensor. An accelerometer measures the acceleration forces acting on an object. Static forces, such as gravity, are constantly acting on objects. Dynamic forces, such as vibration, are those applied to objects at varying rates. Accelerometers produce electrical signals proportional to forces that they are measuring.

There are also different types of accelerometers, with varying strengths and recommended applications. For example, triaxial accelerometers measure acceleration in three orthogonal directions (that is, three axes). Because of this, triaxial accelerometers can measure all of the vibration components affecting an object.

Eddy-Current Vibration Sensors

Eddy-current sensors are versatile non-contact devices that measure displacement using the principles of eddy currents. Eddy currents are loops of electrical current within conductors caused by placing the conductor in a changing magnetic field. Eddy-current vibration sensors are commonly used to measure shaft displacement. This type of misalignment is one of the key mechanical issues that vibration monitoring can detect. Eddy-current sensors are ideal for high-resolution, high-speed vibration measurements.

If using more than one eddy-current vibration sensor, pay close attention to their proximity. If they are too close together, their electromagnetic fields can interfere with one another and reduce the accuracy of any measurements. It is possible to shield sensors.

Wired and Wireless Vibration Sensor Options

Each type of vibration sensor offers different benefits. Wired vibration sensors can record and transmit vibration measurements continuously. In contrast, wireless vibration sensors typically transmit at frequent intervals. In some situations, this distinction makes a difference. Wired sensors can be slightly more expensive to install, in part because of the cabling required. And cable damage can render wired sensors unresponsive. However, there’s also much more data available for vibration analysis.

Wireless vibration sensors, paired with cloud-based software, make it possible to access vibration data from any internet-connected device. Data transfer speeds can vary based on connectivity, location, and other factors. Wireless vibration sensors are comparatively inexpensive to install and highly scalable. Wireless sensors can be placed wherever needed without running cables through walls, floors, and ceilings. Wired sensors are more limited in where they can be placed.

The benefits and drawbacks of both types of vibration sensors can be effectively balanced by using wired and wireless industrial vibration sensors together. Many maintenance software systems make it possible to integrate different types of vibration sensors, even those from different OEMs, into one centralized system.

The Benefits of Industrial Vibration Sensors

Rotating equipment, such as fans, blowers, and pumps, is particularly well-suited to vibration monitoring for identifying and diagnosing faults. Vibration monitoring is an effective way to identify the four most common machine faults: misalignment, imbalance, looseness, and bearing wear. These faults have distinct traits that show up in vibration data.

Vibration monitoring uses sensors and handheld vibration measurement instruments to collect vibration data while machines are running in hopes of catching problems before they become severe.

Industrial vibration sensors capture changes in the amplitude, frequency, and intensity of vibration. Normal wear and tear, as well as other problems, can change the way that bearings, rotors, shafts, and other machine parts vibrate.

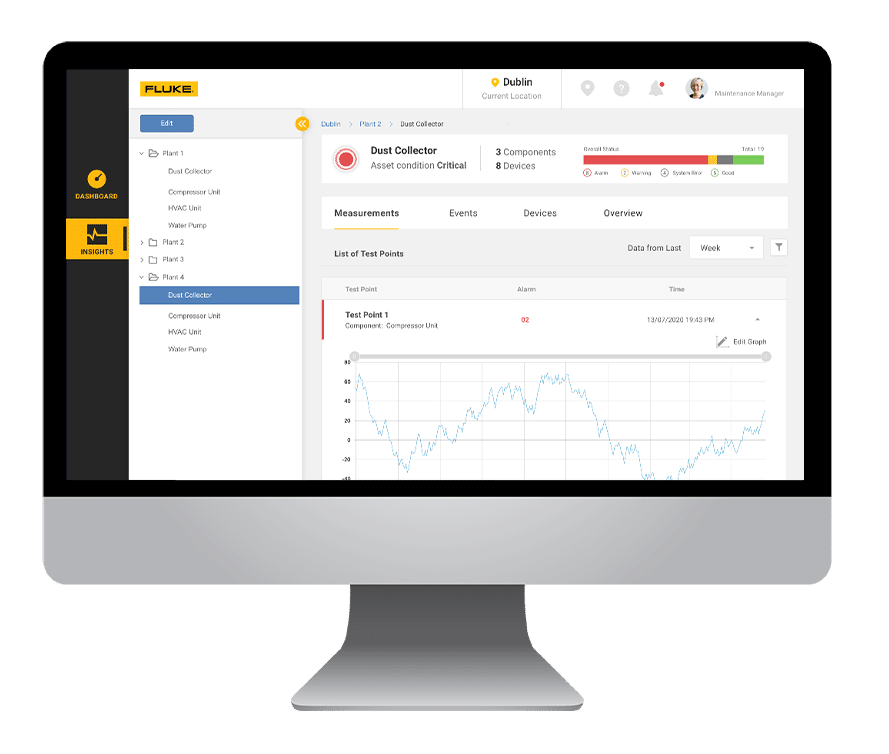

Real-time condition monitoring data collected by vibration sensors lets maintenance teams minimize costly production interruptions and maximize uptime. They’re also an excellent way to start a predictive maintenance program. Vibration sensors also reduce the need for technicians to spend time going asset to asset. When sensors are paired with software, alerts set based on asset-specific parameters can let teams know when an asset needs attention. When teams have real-time knowledge of asset health, they can focus their time and resources on the assets that need attention the most.

How to Choose the Right Vibration Sensor Types

Many types of vibration sensors can capture detailed data that can help identify the root cause behind changes in vibration patterns. Not every asset in a facility requires vibration sensors, though — it’s important to strike a balance and find the best vibration sensor for each machine depending on asset criticality, type, and setting.

A facility’s most production-critical assets may need detailed vibration monitoring continuously and around the clock. Other types of assets may only require vibration measurement snapshots, collected at regular intervals — but not continuously.

There is no one “best” vibration sensor, because the best choice for one asset is not necessarily the best choice for every asset. Choosing the right type of vibration sensor requires knowing, among other things, details about the asset type, operational context, and sensor capability to deliver the data needed to make decisions.

Ready to learn more about types of vibration sensors? Speak to a specialist.