What is Vibration Measurement?

Vibration measurement is a key tool in today’s fast-advancing Industrial Internet of Things-driven maintenance and reliability world.

To ensure you select the best tool for your organization, it’s important to know if a given vibration sensor or industrial vibration measurement device will interface with your present and future systems, including hardware and asset management software.

The Industrial Internet of Things (IIoT) powers the interface between people, systems, and machinery. The connectivity it provides offers maintenance teams new opportunities to extend machine lifespans and increase overall efficiency.

For instance, with condition monitoring tools, reliability professionals can predict asset failures and receive critical machine health data instantly from anywhere. And in the future, vibration analysis combined with machine learning (ML) and artificial intelligence (AI) will be able to drive repair recommendations. But to unlock that future, maintenance teams must be prepared with the right vibration measurement tool kit.

Which Vibration Measurement Tool Should I Use and Why?

Before deciding how to measure vibration, take a look at where your organization stands in its reliability journey. Are you happy with your current maintenance and operations practices? Do you have the connectivity and infrastructure to implement predictive maintenance (PdM) strategies or a vibration monitoring program?

A lack of resources is a common reason why some organizations struggle with their vibration monitoring programs — including choosing the wrong vibration measurement tool for their needs. Fluke Reliability offers comprehensive remote condition monitoring services, hardware, and software to get you started, keep you on track, and ensure you succeed.

Vibration Measurement Data is Information Rich

Vibration measurements can help maintenance teams determine the health of machines. By collecting vibration data, teams can detect if and when a machine’s condition changes. Vibration measurement can also be used to diagnose the cause at the root of that change. Crucially, vibration measurements can also offer information for safe machine operation.

Vibration measurement is normally a non-intrusive measurement procedure, and it can be carried out with the machine running in its normal operating condition.

Vibration is simply a sound wave, and each component of a machine has a unique sound (or frequency) that is not detectable to the human ear. Sensors have the ability to detect these.

The amplitude of vibration depends on the magnitude of the excitation force, the mass and stiffness of the system, and its damping. Some level of vibration is normal in machinery. Some sources of vibration are machine tolerances, machine structure, bearing design, loading and lubrication, machine mounting, and rolling and rubbing between moving parts.

5 Types of Vibration Measurement Tools

The following vibration measurement tools often help reliability professionals start a predictive maintenance (PdM) or remote condition monitoring program.

1. Handheld Vibration Meter Tools

Best Usage:

A handheld vibration measurement tool like the Fluke 805 FC Vibration Meter is best when you need a highly reliable screening device that can provide repeatable, overall vibration readings. Unlike a pen, the Fluke 805 also measures specific variables, including bearing condition and temperature.

The severity scale is easy to understand and displays simple texts (Good, Satisfactory, Unsatisfactory, Unacceptable) to indicate bearing condition and overall vibration. The vibration measurement device reads a wide range of frequencies, and the data is accessible from anywhere via a smart device, such as a laptop or mobile phone.

2. Portable Vibration Tester Tools

Best Usage:

A portable vibration tester is a strong great option when critical machines can be safely and easily reached by a technician. And while both handheld vibration testers and vibration analyzers can capture vibration data and diagnose machine faults, they do have different capabilities.

The Fluke 810 Vibration Tester uses an analytics engine to diagnose machine issues and provides onsite vibration analysis on one screen. It captures a narrow data window.

3. Handheld Vibration Analyzer Tools

Like vibration testers, a portable vibration analyzer can provide users with immediate vibration measurement information about machinery health, including motors, fans, and blowers. Both can identify the four most common faults: imbalance, misalignment, looseness, bearing damage. They can also often tell you the fault location and severity.

However, unlike vibration testers, a handheld vibration analyzer such as the VIBXpert II by Prüftechnik can collect almost any type of vibration measurement data. These vibration measurement tools also can help teams correct machine imbalance and connect to multiple types of sensors. However, because of their sophistication, vibration analyzers often need an expert to interpret the detailed data.

4. Wireless Vibration Analysis Sensor

Best Usage:

A wireless vibration analysis sensor is best if your organization has dozens of critical machines. When a critical asset fails, it can shut down production and even harm other machines. These sophisticated sensors alert you of potential machine faults well in advance, including showing the severity of the problem, so you can act to prevent failure.

What Does a Wireless Vibration Analysis Sensor Do?

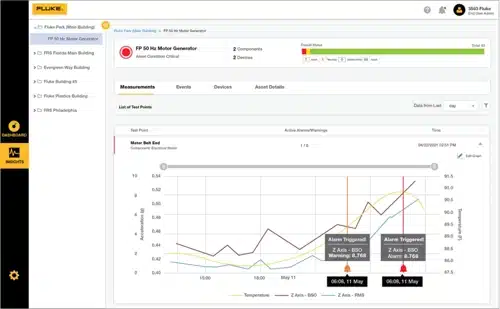

Wireless vibration sensors like the Fluke 3563 Analysis Vibration Sensor track machine performance and capture in-depth data with a powerful piezo sensor. The data provides reliability professionals with insight into production-critical machinery problems. Quick results give maintenance teams enough time to make informed decisions before machines fail.

5. Wired Vibration Monitoring System

Best Usage:

A wired vibration monitoring system is best for condition monitoring of production-critical machines. For example, the VIBGUARD IIoT from Prüftechnik can monitor turbine generators, paper machines, high-speed spindles, and multiple drive machines. These advanced vibration measurement tools provide complete vibration analysis for complex machines.

What Does a Wired Vibration Monitoring System Do?

A wired vibration monitoring system captures large amounts of high-resolution vibration measurement data. It allows vibration analysis for a vast range of machinery faults, resonances, processes, and structures, and enables predictive maintenance.

Helpful Tips for Choosing a Vibration Measurement Tool

- Think about the machinery problems you want to solve first and why. Carefully review your most costly maintenance problems. Which of your machines fail most often, what causes the problems, and how do they impact production?

- Take advantage of a manufacturer’s offerings. A trial lets your organization test-drive a vibration measurement tool before buying it. Depending on the vendor, the organization also receives expert support to ensure proper pilot setup and success better. For example, Fluke Reliability offers extensive training and remote condition monitoring services.

- Perform an asset criticality analysis (ACA) to ensure your vibration measurements are focused on the right machinery. An asset criticality assessment uses data to accurately identify the actual business value of your most essential assets. Stakeholders use agreed-upon criteria to assess, classify, and rank assets and group them as production critical, semi-critical, and less critical.

Vibration measurement is essential to any maintenance program. Vibration is the “pulse” of your machines, giving you invaluable insight into asset health and performance. Fortunately, you don’t have to be an expert in vibration measurement to take advantage of the benefits of vibration monitoring and analysis for your equipment. Here, we explain how vibration measurement works, why it’s important, and how it can maintain the health and increase the lifespan of your assets.

Why Vibration Measurement is Important

When industrial equipment is running, some level of vibration is normal. When a machine’s vibration pattern changes, it can signal existing or potential faults. Excessive, erratic, or otherwise abnormal vibrations are often the first sign of a problem with your machines. Left unchecked, the underlying problems can escalate to the point where the machine will eventually fail. In addition, uncontrolled vibration can lead to further damage to your equipment.

With advances in Industrial Internet of Things (IIoT) technologies, the industry has moved from preventive maintenance toward condition-based and predictive maintenance strategies. These leverage real-time asset health data to optimize maintenance schedules and prevent unplanned downtime.

A vibration measurement tool gathers condition data from machines. Data from these devices can be used to diagnose issues such as worn bearings, misalignment, and more, so they can be resolved before they lead to failure and downtime. Vibration monitoring can identify early signs of wear in machines and serve as a powerful indicator of machine health and performance.

Vibration Measurement Instruments

There are a variety of instruments that can be used to capture machine vibration, most of which do so by measuring changes in acceleration. This is called an accelerometer, and it is one of the most effective technologies for monitoring and analyzing machine vibrations, both long-term and in real-time. Vibration can be measured both by handheld devices operated by maintenance personnel and by sensors affixed to machine components.

Handheld Vibration Meters and Testers

Handheld vibration meters and portable testers can be used to manually collect data at a given point in time — for example, during route-based maintenance. These devices capture accurate and precise readings that can be used to diagnose problems and inform your maintenance program.

Handheld vibration analyzers can be an effective diagnostic tool, but they do have their limitations. They capture vibration levels at a single point in time. In addition, measurement depends on human action: a technician must go up to the machine, take a reading, record that reading, etc.

Vibration Sensors

Vibration sensors can be installed on critical points on a machine to monitor vibration patterns in real-time, around the clock. This offers many advantages. For example, continuous monitoring means you have more data about how your machine is performing and its health over time.

Real-time monitoring also means you can be alerted to a problem right away when there’s still time to protect the machine from further damage. There are both wired and wireless vibration sensors.

Types of Vibration Sensors

Today, the vast majority of vibration sensors are accelerometers, which means that the sensors measure acceleration. MEMS and piezoelectric sensors are two of the most common types of accelerometers used to measure machine vibration.

MEMS Vibration Sensors are best suited for frequency ranges of 0 to 1000 Hz. This frequency range is typically where imbalance, misalignment, and looseness can be identified. MEMS sensors are cost-effective and provide long battery life, making them ideal for large-scale vibration monitoring programs.

Piezoelectric Vibration Sensors are best suited for frequency ranges over 1000 Hz, including for monitoring bearings, compressors, and gearboxes. These sensors can be used to identify issues with gear mesh and motor bars, for example.

What Is Vibration?

Vibration describes a process of oscillation, or back and forth displacement, around a stable center. When you strike a tuning fork, it vibrates. Motor-driven tools also vibrate when in use.

No two assets vibrate in exactly the same way. Factors like size, stiffness, energy input, and coupling all impact the frequency and amplitude of an asset’s vibration levels. Environmental factors like heat also have an impact on vibrations.

Why does this matter? Because vibration levels are a great way to track changes in asset health.

Every rotating machine has its own vibration “signature,” or baseline pattern. When that pattern changes, there’s a good chance that something is wrong with the machine. Even small changes in vibration levels can point to new problems – like misalignment, bearing faults, unbalance, or a bent shaft.

The sooner you spot those issues, the more quickly your team can repair them. But if left unaddressed, they can lead to serious defects that could shut down your machines. In other words, paying attention to vibration levels can save you time, resources, and labor.

How Is Vibration Measured?

Technicians have a huge range of tools they can use to measure vibrations, from hand-held vibration meters to wireless vibration sensors. Depending on your needs, technicians can take vibration measurements as part of a route-based inspection, or they can collect data on a continuous basis.

Most vibration measurements are taken using an accelerometer, a tool that measures the shocks and vibration emitted by assets and components. Many accelerometers – including most wireless sensors – rely on piezoelectric technology, which converts physical vibrations into electrical signals.

Wireless vibration sensors can continuously collect vibration data, which means you can see exactly how your assets are performing while they’re in operation. You can also leverage such data by sending it to a Computerized Maintenance Management System (CMMS)to gain greater insight into asset health and help with maintenance planning.

A good CMMS will also store your vibration data so that it’s easy to access, wherever and whenever. This helps you make informed decisions about scheduling repairs, ordering parts, or buying new equipment.

What is the Unit of Measurement for Vibration?

There are a few different ways to measure vibration levels. Each method uses its own units of measurement. Most plants use more than one way of measuring vibration, so it’s a good idea to familiarize yourself with a few of the approaches.

Vibration can be measured in frequency, velocity, acceleration, and displacement. To put it briefly:

- Frequency measures the number of full oscillations, or cycles, that a vibrating object goes through per second. Frequency is measured in Hertz (Hz).

- Displacement measures how far a vibrating object moves from its central, fixed position. A higher level of displacement indicates a more dramatic vibration. Displacement is typically measured in meters (m) or millimeters (mm).

- Velocity measures changes in the rate of displacement. The basic unit is millimeters per second (mm/s).

- Acceleration measures changes in velocity over time. Depending on the vibration levels, acceleration can be measured in m/s2 or mm/s2.

What Are the Three Most Important Parameters Used to Measure Vibration?

Typically, technicians look at three parameters when they measure vibration levels: frequency, displacement (or amplitude), and acceleration. In short, these parameters measure the size and intensity of vibration levels. Together, they can help teams pinpoint the root cause of vibration, determine how severe it is, and set maintenance priorities.

Looking at changes in displacement levels, for example, can help teams determine if a machine is out of balance. Performing frequency analysis can then help pinpoint exactly which component is causing the increase in overall vibrations. Ultimately, a multi-pronged approached to vibration analysis saves you both time and money.

How Do Technicians Measure Vibration Frequency?

Most of the vibration sensors used today are accelerometers, which measure acceleration. MEMS vibration sensors are designed to measure vibration levels for frequency ranges from 0 to 1,000 Hz. Piezoelectric vibration sensors are ideal for frequency ranges greater than 1,000 Hz.

Technicians may also choose to break down these vibration signals into their individual frequency components. The resulting graph is called a frequency spectrogram, and it can offer teams valuable insight into which component is driving the increased vibration levels. A good vibration monitor can also perform Fast Fourier Transform (FFT) analysis, breaking down the vibration reading into a frequency spectrogram.

There are many different ways to measure vibration levels. And when done right, vibration measurement can unlock a storehouse of actionable insights into machine health. Effective vibration analysis can help you stay ahead of serious problems, keep your plant up and running, and lead to major increases in your productivity.

For more information, see our Guide to Vibration Sensors for Motors.