Introduction to Belt Alignment

In machine maintenance and reliability, understanding the criticality of proper belt alignment is essential. This comprehensive guide details the importance of belt alignment in various industrial applications, focusing on how advanced strategies like laser belt alignment and laser pulley alignment have revolutionized maintenance practices. Let’s explore how alignment tools, including Prüftechnik PullAlign, contribute to the efficiency and longevity of machinery.

What is Belt Alignment?

Belt alignment is the process of aligning the pulleys of a belt-driven system to ensure optimal performance and longevity of the belts. Proper alignment is critical as it prevents premature wear and tear, reduces vibration, and enhances the efficiency of the power transmission system. Misaligned belts can increase mechanical stress and energy consumption, causing significant downtime and repair costs.

Importance of Proper Belt Alignment

Correct belt alignment is essential for several reasons:

- Reduces Belt Wear: Properly aligned belts distribute tension uniformly across their entire width, significantly reducing wear and extending belt life.

- Decreases Vibration: Alignment minimizes machinery vibrations, which can reduce noise and lower the risk of damage to other components.

- Improves Energy Efficiency: Aligned belts operate more smoothly and efficiently, reducing the energy required to transmit power effectively.

Types of Misalignment

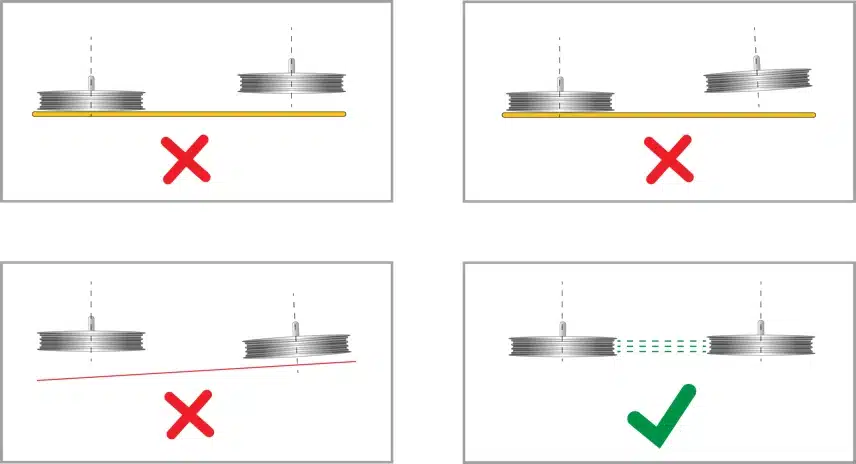

Misalignment in belt-driven systems can be categorized into two types:

- Angular Misalignment: This occurs when the pulleys are not parallel to each other, causing the belt to undergo uneven wear.

- Parallel Misalignment happens when the pulleys are not on the same plane, leading to the belt drifting off the pulleys or wearing unevenly.

Techniques for Achieving Belt Alignment

To achieve and maintain proper belt alignment, various tools and methods can be employed:

- Laser Alignment Tools: These provide high precision by projecting a laser beam that helps identify and correct misalignment.

- Straightedges and String Methods: Traditional techniques use a straight line or string to check the alignment visually.

What are the Correct Procedures for Aligning Belts?

Belt alignment is a crucial maintenance task that involves adjusting the positions of pulleys to ensure the smooth operation of belts in machinery. Proper alignment minimizes wear and tear on belts and pulleys, reduces unnecessary mechanical loads, and enhances overall equipment efficiency. It aligns pulley grooves to facilitate uniform belt movement, preventing premature wear and operational issues.

Understanding Belt Alignment: An Essential Aspect of Machinery Maintenance

Belt alignment is a critical process in the maintenance of rotating machinery, pivotal for ensuring optimal performance and longevity of equipment. This process involves adjusting the mechanical components, primarily belts, and pulleys, to ensure they are perfectly aligned and parallel.

- Alignment precision: The core goal of belt alignment is to ensure the belt runs smoothly along the pulley grooves without lateral movements. Proper alignment reduces the risk of the belt slipping or wearing unevenly.

- Tools and techniques: Advanced tools, such as laser belt alignment, have become industry standards for achieving precise alignment. These tools, offered by companies like Prüftechnik, provide accurate measurements and adjustments, surpassing traditional methods in efficiency and accuracy.

- Maintenance and longevity: Regular belt alignment checks are crucial to preventive maintenance care. They help prolong the life of belts and pulleys, ensuring machinery operates efficiently and reducing the need for costly repairs or replacements.

The Significance of Belt Alignment in Industrial Settings

Belt alignment is a pivotal aspect of maintaining rotating machinery. Misaligned belts can lead to numerous problems, including premature wear of belts and pulleys, increased energy consumption, and the potential for catastrophic equipment failures. Precision is even more crucial in specific applications like elevator pulley alignment due to the safety implications.

Understanding the Basics of Belt and Pulley Alignment

Belt alignment ensures that belts run smoothly, without lateral movements that could lead to wear and tear. A reliable belt alignment tool is indispensable for professionals maintaining these systems.

Advanced Tools for Enhanced Accuracy: Laser Pulley Alignment Tool

Transitioning from traditional methods to laser-based tools for pulley alignment has marked significant advancement in the field of belt alignment. These tools offer unparalleled precision, making the alignment process more efficient and accurate.

The Evolution of Laser Belt Alignment Tools

The introduction of the laser belt alignment tool marked a turning part in maintenance technology. Unlike manual methods, these tools provide real-time feedback and high precision, ensuring optimal alignment with minimal effort.

Benefits of Using a Laser Pulley Alignment Tool

Using a laser pulley alignment tool comes with several advantages:

- Increased accuracy: Laser tools provide exact measurements, which are crucial for the proper functioning of machinery.

- Time efficiency: With quick setup and operation, these tools reduce downtime significantly.

- Long-term cost savings: Proper alignment extends the life of belts and pulleys, reducing replacement costs.

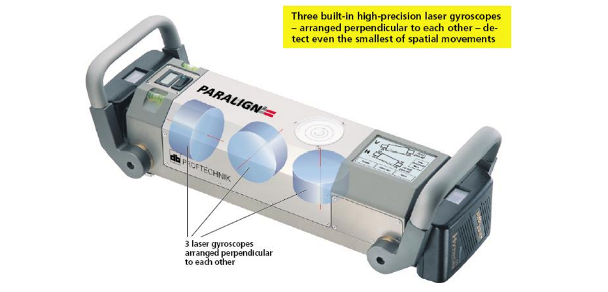

Prüftechnik PullAlign: A Game-Changer in Belt Alignment

Prüftechnik PullAlign is a leading laser alignment solution for belts and pulleys. It exemplifies precision engineering and user-friendly design, making it an ideal choice for maintenance professionals.

Key Features of PullAlign

- Advanced laser technology: Ensures high accuracy in alignment tasks

- Ease of use: Designed for intuitive operation, suitable for professionals at all skill levels

- Durability: Built to withstand harsh industrial environments

Applications of PullAlign in Various Industries

PullAlign assists experts in multiple sectors, including manufacturing, automotive, and utilities management. Its versatility makes PullAlign suitable for various applications, from standard rotating machinery alignment to specialized tasks like elevator pulley alignment.

Best Practices in Belt Alignment

For maintenance professionals, it’s crucial to adhere to best practices in belt alignment in order to avoid unplanned downtime. Regular inspections, routine upkeep with a pulley alignment tool, and continuous monitoring are essential to maintaining machinery health.

- Regular checks: Periodic inspections help detect misalignment early.

- Precision tools: Utilize tools like the belt alignment tool for accurate adjustments.

- Training: Ensure that maintenance staff are well-trained in using advanced alignment tools.

The Consequences of Misaligned Pulleys in Machinery

When pulleys are not aligned correctly in machinery, it can impact the equipment’s efficiency and longevity and lead to operational issues. Understanding these repercussions is crucial for maintenance and reliability professionals.

- Increased wear and tear: Misalignment causes uneven wear on belts and pulleys, leading to premature failure. This necessitates more frequent replacements and maintenance, incurring additional costs.

- Excessive vibration: A common consequence of misaligned pulleys is increased vibration. This puts extra stress on machine components and can lead to noise issues and reduced operational comfort.

- Higher energy consumption: Misaligned pulleys force motors to work harder to achieve the same level of performance, which leads to increased energy consumption. This inefficiency results in higher operational costs and a larger carbon footprint.

- Reduced machine life: Continuous operation with misaligned pulleys can strain the entire machinery system, from bearings to motor mounts. This undue stress reduces the overall lifespan of the machinery.

- Safety risks: In severe cases, misalignment can lead to belt slippage or breakage, posing safety risks to operators. It can also cause operational downtime while the machine is repaired.

Using advanced alignment tools like those from Prüftechnik can prevent these issues, ensuring belts and pulleys are perfectly aligned for optimal machine performance. Regular checks with precise alignment tools are a key preventive measure in machinery maintenance.

Correcting a Misaligned Pulley: Effective Strategies for Optimal Machine Performance

Fixing a misaligned pulley helps maintain the efficiency and longevity of machinery. Here’s a straightforward approach to rectify this common issue:

- Diagnose the misalignment: First, identify the type and extent of misalignment using a reliable device, such as a laser pulley alignment tool. Prüftechnik’s advanced alignment systems are particularly effective, offering precise angular and parallel misalignment measurements.

- Loosen the pulley mounts: Once you have detected misalignment, slightly loosen the mounts or bolts securing the pulley. This step is essential to allow for adjustments without exerting undue stress on the pulley or the belts.

- Adjust the pulley position: Based on the alignment readings, adjust the position of the pulley. If the pulley is angularly misaligned, it may require tilting to align with the belt’s path. For parallel misalignment, shift the pulley either closer or further away from the belt.

- Re-tighten and re-check: After making necessary adjustments, securely re-tighten the mounts or bolts. Be sure to re-check the alignment using the laser alignment tool to ensure the issue has been fully corrected.

- Test run and monitor: Finally, perform a test run of the machinery. Monitor for any unusual noises or vibrations, which could indicate unresolved alignment issues.

By following these steps and using tools like Prüftechnik PullAlign, you can effectively fix a misaligned pulley and ensure smoother operation and reduced wear on your machinery.

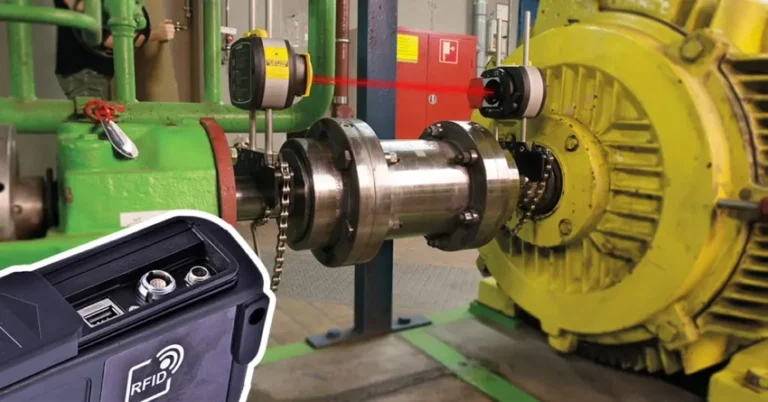

Here’s a basic guide on how to use these tools:

- Set up your tool: Begin by attaching the laser-emitting component of the pulley alignment tool to one of the pulleys. This is typically done using a magnetic bracket or a mounting fixture that securely fastens the tool in place.

- Align the laser: Turn on the laser and adjust it so that the beam points towards the corresponding pulley. The laser should ideally strike the target area, which is often a reflector or receiver mounted on the opposite pulley.

- Measure misalignment: Observe the laser’s position on the target. Modern pulley alignment tools, such as those offered by Prüftechnik, often have indicators or digital readouts to show the exact degree of misalignment. Both parallel and angular misalignment can be reported.

- Make adjustments: Based on the readings, make necessary adjustments to the pulleys. This might involve shifting the position of the pulleys or modifying their angle until the laser aligns perfectly with the target center.

- Re-check alignment: After adjustments, re-check the alignment using the tool to ensure that the pulleys are perfectly aligned. Repeat the process if necessary.

Using a pulley alignment tool like Prüftechnik PullAlign provides a high level of precision, ensuring the longevity and efficiency of machinery while reducing wear and tear on components.

Exploring Methods of Belt Alignment

Belt alignment is a critical process for maintaining the efficiency and longevity of machinery. Two primary methods are widely recognized: traditional and laser alignment.

- Traditional alignment methods: These include using straightedges, rulers, or string lines. Technicians visually inspect the alignment between pulleys — a technique that relies heavily on the operator’s experience and skill. However, this method’s accuracy is often limited due to human error and the inability to measure minute misalignments.

- Laser belt alignment tools: A more advanced and precise method involves the use of laser alignment tools. Devices like Prüftechnik’s advanced alignment systems, which are at the forefront of alignment technology, project a laser beam across pulleys. This method provides high-precision measurements, enabling technicians to achieve exact alignment efficiently. Laser tools offer significant advantages over traditional methods, including enhanced accuracy, time efficiency, and the ability to diagnose alignment issues with greater accuracy.

Adopting the right belt alignment method, particularly laser-based tools, enhances optimal performance of rotating machinery. It ensures prolonged equipment life, reduced wear on components, and significant energy savings, aligning with best practices in industrial maintenance.

How Do I Know if My Belt is Misaligned?

Identifying belt misalignment is crucial for maintaining the efficiency and longevity of belt-driven systems. Recognizing the signs of misalignment early can help prevent costly repairs and downtime. Here are key indicators that your belt may be misaligned and steps you can take to verify alignment issues.

Signs of Belt Misalignment

- Abnormal Noise: Unusual sounds such as squealing or screeching from the belt system often indicate that the belt is not running smoothly over the pulleys.

- Visible Wear and Tear: Uneven wear on the belt, such as fraying edges or visible glazing, suggests that the belt is rubbing against pulley flanges or not seated properly.

- Vibration: Excessive vibration in the belt or the driven components can signal misalignment. This vibration can also cause other machinery malfunctions.

- Belt Tracking Issues: If the belt continually drifts off-center or appears to wander on the pulley, it is likely misaligned.

- Increased Energy Consumption: Misaligned belts require more energy to achieve the same level of performance as aligned belts, leading to unexpectedly high power usage.

How to Check for Belt Misalignment

To diagnose belt misalignment, you can use several methods ranging from visual inspections to more advanced techniques:

- Visual Inspection: Look for uneven wear on the belt and pulleys. Check if the belt runs centrally on the pulleys. Any sideward movement or slippage can indicate misalignment.

- Straightedge or String Line: Place a straightedge or taut string along the faces of the pulleys to see if they line up perfectly. Any deviation from a straight line suggests angular or parallel misalignment.

- Laser Alignment Tools: These provide a highly accurate way to assess alignment. The laser helps visualize the alignment between the pulleys, showing deviations clearly.

- Check Pulley Grooves: Sometimes, the issue might be with the pulleys. Check for wear in the grooves, which can affect the belt’s position and indicate that maintenance or replacement of the pulley is needed.

Preventative Measures

Regular maintenance is the best way to prevent misalignment. This includes:

- Routine Inspections: Regularly scheduled checks can help catch misalignment early before it leads to belt or machinery damage.

- Proper Installation: Ensure that belts are properly tensioned and aligned at installation. Recheck alignment after the belt has had some initial run-time, as new belts can stretch.

- Training and Documentation: Train maintenance staff on the importance of belt alignment and proper techniques for checking and correcting alignment. Keep records of maintenance and inspections to track the system’s history.

Knowing how to identify and correct belt misalignment is essential for maintaining operational efficiency and prolonging the life of belt-driven systems. You can ensure your machinery operates smoothly and efficiently by routinely monitoring your belts and responding promptly to any signs of misalignment.

How Do You Check a Belt Pulley Alignment?

Proper alignment of belt pulleys is essential for efficiently operating belt-driven systems. Misalignment can lead to increased wear on belts and pulleys, reduced system efficiency, and potential equipment failure. Here’s a step-by-step guide on how to check a belt pulley alignment to ensure your machinery operates optimally.

Steps to Check Belt Pulley Alignment

- Visual Inspection: Start with a visual inspection of the belt and pulleys. Look for signs of wear or damage on the belt, such as cracking, fraying, or glazing. Check the pulleys for any visible damage or wear that could affect the alignment, like worn grooves or dents.

- Power Down Equipment: Ensure that the machinery is turned off and adequately locked out before checking or adjusting the alignment. This prevents any accidental startup during maintenance.

- Use a Straightedge or String: Place a straightedge or tight string across the faces of the pulleys. The straightedge should lie flat against both pulley faces without any gaps. If using a string, it should be taut and align precisely with the grooves of both pulleys from end to end.

- Check for Parallel Alignment: Observe the gap between the straightedge or string and the pulley faces. There should be no visible gap at any point along the pulleys. Use a feeler gauge to measure any gaps if necessary. This helps determine if there’s a need for adjustment.

- Laser Alignment Tool: Set up the laser alignment tool according to the manufacturer’s instructions. Position the laser emitter on one pulley and the target on the opposite pulley. Turn on the laser and observe where the beam lands on the target. The laser should hit the same marked spot on the target across all angles of pulley rotation.

- Adjust as Needed: If the straightedge, string, or laser shows misalignment, adjust the position of the pulleys. This might involve loosening the mounting bolts and shifting the pulley slightly until the correct alignment is reached. After adjustments, recheck the alignment using the same tool to ensure accuracy.

- Check Belt Tension: After aligning the pulleys, check the belt tension to ensure it is not too tight or loose. Improper tension can also affect pulley alignment and belt lifespan.

- Test Run and Monitor: Once adjustments are made and everything is tightened, perform a test run of the machinery. Monitor the operation closely for any unusual noises or vibrations that could indicate an issue with the alignment or installation.

Regular Maintenance and Documentation

Proper records of maintenance and alignment checks can help track the performance and wear of belts and pulleys over time. Regular checks and timely adjustments can prevent major breakdowns and extend the life of your equipment.

By following these steps, you can effectively check and maintain the alignment of belt pulleys, ensuring your machinery operates efficiently and reliably.

Why is Belt Alignment Important?

Belt alignment is a crucial preventive maintenance step ensuring belt-driven machinery’s smooth operation. Proper alignment of belts and pulleys helps extend the equipment’s life, improve energy efficiency, and prevent costly downtime. Understanding the significance of belt alignment can help you maintain your machinery more effectively and avoid the negative implications of misalignment.

Key Benefits of Proper Belt Alignment

- Extended Belt and Pulley Life: Misaligned belts can suffer from uneven wear, increased friction, and excessive stress on the belt and pulley edges. This leads to faster deterioration and the need for frequent replacements. Proper alignment reduces wear and extends the lifespan of both belts and pulleys, thereby reducing the cost of parts and maintenance.

- Improved Machine Efficiency: A misaligned belt can cause slippage and decreased contact with the pulley, leading to power loss and reduced operational efficiency. Correct alignment ensures maximum contact and efficient power transmission from the motor to the machine, enhancing the system’s overall performance.

- Reduced Energy Consumption: Misalignment often results in higher energy consumption because the machinery has to work harder to overcome the added resistance and inefficiencies caused by improperly aligned belts. Ensuring that belts are appropriately aligned helps reduce energy costs, as the system operates more smoothly and requires less power to achieve the same output level.

- Decreased Vibration and Noise: Vibration and noise are common symptoms of belt misalignment. These can lead to further damage and wear on other components, including bearings and shafts. Aligning belts correctly minimizes vibrations and reduces noise levels, contributing to a safer and more pleasant working environment.

- Prevention of Unexpected Downtime: Misalignment is a leading cause of mechanical breakdowns in belt-driven systems. Unexpected downtime affects productivity and involves costs related to repairs and lost revenue. Regular checks and maintenance of belt alignment can prevent these unplanned stoppages.

- Enhanced Safety: Proper belt alignment eliminates risks associated with belt snapping, pulley failures, and other mechanical issues that could pose safety hazards to operating personnel. Ensuring that your belts are correctly aligned contributes to a safer operating environment.

Monitoring and Maintenance

It would help to incorporate belt alignment checks into your regular maintenance schedule to reap these benefits. Use alignment tools such as laser aligners for high precision, and consider training for maintenance personnel to recognize and correct alignment issues. Documenting each inspection and maintenance action can help track the condition over time and identify when adjustments are necessary.

Conclusion: Embracing the Future of Maintenance with Advanced Alignment Tools

Belt alignment plays a vital role in the maintenance and reliability of industrial machinery. The advent of tools like the laser belt alignment tool and Prüftechnik PullAlign has significantly enhanced the efficiency and accuracy of these processes. As we continue to embrace these advancements, the future of industrial maintenance looks promising, marked by increased reliability, reduced downtime, and cost savings.

Learn More About Prüftechnik PullAlign

Discover the efficiency and precision of Prüftechnik PullAlign for your belt alignment needs. Visit Prüftechnik PullAlign tool to explore how this innovative solution can transform your maintenance procedures. Embrace the future of maintenance with Prüftechnik’s PullAlign – the smart choice for professionals in the field.