Through the years, most plants and facilities end up using a hodge-podge of options to connect their wireless vibration sensors. As they expand, relocate, install technology updates, or implement predictive maintenance strategies, maintenance leaders find themselves adopting things like Wi-Fi, LTE, and Ethernet connections. One site in a facility may be able to use Wi-Fi vibration sensors, while another may require Bluetooth vibration sensors, and a third site could need LTE connections.

Fortunately, some modern wireless vibration sensors now come with dual and triple-connection capabilities. So, you buy one IIoT vibration sensor system that can use either Wi-Fi, Ethernet, and even LTE.

Adding condition monitoring technology requires a wireless sensor network (WSN). A WSN enables connectivity and data transmission.

How Will you Transmit and Receive Wireless Condition Monitoring Data?

To implement a vibration monitoring program, organizations need to know how to transmit and receive wireless condition monitoring data. Whether Wi-Fi, LTE, Bluetooth, or Ethernet, any network connectivity option involves compromises.

Wireless Connectivity Trade-Offs

- Power consumption

- Range, latency (speed)

- Bandwidth (size)

- Reliability

Before you implement new IIoT technology, you should understand your wireless sensor connectivity options and which ones will work best in your facility. Armed with that knowledge, you can successfully connect all your condition monitoring devices.

You should also know how you’ll apply the technology. For instance, which machines will you place vibration sensors on, in which locations, and in what types of environments?

Connecting Wireless Vibration Sensors

IIoT-enabled data transmission and connectivity happens in various ways, including via Wi-Fi, Ethernet, and LTE. Although other methods exist, these three represent the most common ways to achieve wireless connectivity and build a framework for connected reliability.

What are LTE Vibration Sensors?

LTE (Long Term Evolution) is a wireless broadband communication standard for telephones and mobile devices (telecommunications). LTE also called “4G”, is the fourth generation of mobile communication technology. It continues to evolve with the new enhancements due to 5G. LTE aims to boost the capacity and speed of wireless data networks using new DSP (digital signal processing) techniques.

What are Wi-Fi Vibration Sensors?

W-Fi is commonly used for devices needing a direct connection to the internet and for transferring large files and is associated with higher-bandwidth data transfer applications. It comprises a group of wireless network protocols based on the IEEE (Institute of Electrical and Electronics Engineers) 802.11 standards.

IEEE 802 standards help ensure internet services and technologies abide by a set of recommended practices so network devices can all work together efficiently. Like LTE, it continues to advance to meet ever-growing connectivity needs.

What are Ethernet Vibration Sensors?

Ethernet is a standard technology that enables devices to connect in a wired local area network (LAN) or wide area network (WAN). It involves a hardwired connection to the internet via Ethernet cables.

The devices transfer data via a protocol, a set of rules, or a shared network language.

Depending on various factors, an Ethernet connection is faster than a Wi-Fi connection and can offer better reliability and security.

A Wi-Fi connection transmits data via wireless signals, while an Ethernet connection transmits data over cable. An Ethernet connection is generally faster than a Wi-Fi connection and provides greater reliability and security.

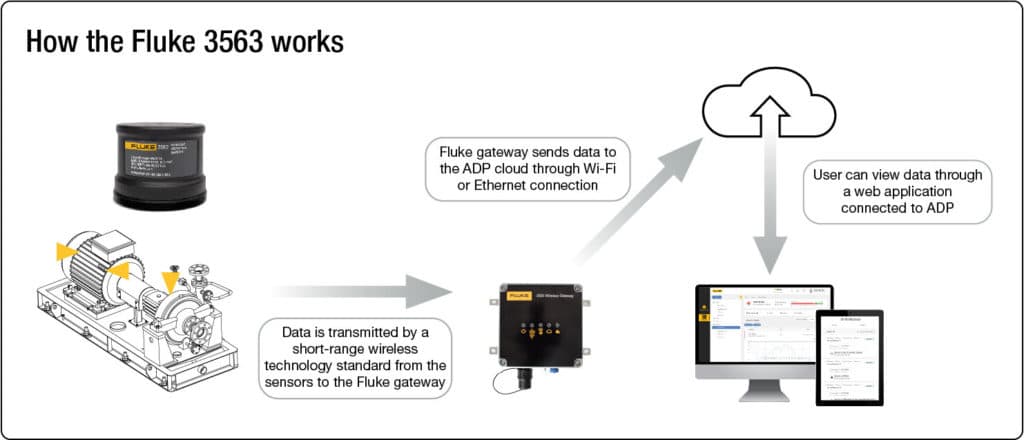

What is a Gateway?

A gateway bridges two or more networks with different transmission protocols together. It operates as an entry and exit point for a network. All data must go through or communicate with the gateway before being routed.

Condition Monitoring Network Connectivity and Security

Many organizations want to accelerate their digital transformation by implementing a condition-based maintenance (CBM) monitoring program. Unlike calendar-based preventive maintenance (PM), machinery maintenance is only performed when necessary and is based on the asset’s condition.

Unfortunately, a plan to integrate new technology can be nixed instantly because an organization discovers that its existing network infrastructure won’t support a CBM monitoring program.

It’s critical to involve the IT department before implementing new technology. Your IT department likely knows the existing system well and its connectivity capacity or lack of it. Data security, another crucial component when implementing wireless vibration condition monitoring, must also be considered.

Your organization might need expert help or lack the resources or time to understand and examine IIoT connectivity options and blockers. Many device manufacturers and system suppliers offer provider services solutions and experienced experts to assist you with your connected reliability journey.

Want to learn more about connecting wireless vibration sensors? Speak to a specialist.