If you’re looking for a way to keep your machines running better for longer, vibration analysis can be a huge help. Vibration analysis is a crucial component of any industrial reliability program. It helps teams monitor machine health, predict maintenance needs, and diagnose defects quickly.

This article explains what vibration analysis is and what it can do for your organization. We’ll also closely examine the tools, software, and methodology used for vibration analysis.

Vibration analysis is at the core of reliability-centered maintenance (RCM) and predictive maintenance (PdM) programs. It’s often coupled with other non-destructive testing maintenance technologies like oil analysis, thermography, ultrasonic testing, and motor current analysis.

What is Vibration Analysis?

Vibration analysis is the process of measuring and analyzing your asset vibration patterns. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime.

Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. This avoids costly cascade failures and allows time for maintenance planning, procurement, and safe shutdown of equipment.

As a key component of any condition monitoring or predictive maintenance program, vibration analysis provides the insights maintenance leaders need. That way, decision-makers can stay ahead of machine failure and drive more efficient maintenance planning.

How Does Vibration Analysis Work?

Every component of rotating machinery vibrates at a discrete and quantifiable rate when it’s in use. Some degree of vibration is normal. But when an asset starts to vibrate excessively or at an abnormal frequency, it may indicate that your asset is malfunctioning or deteriorating.

Vibration analysis lets you pinpoint the source of vibration, diagnose it, and then take the appropriate action to correct it. Maintenance teams use a variety of tools to collect vibration data from critical assets and components. Then, they can analyze that data for insights into asset health.

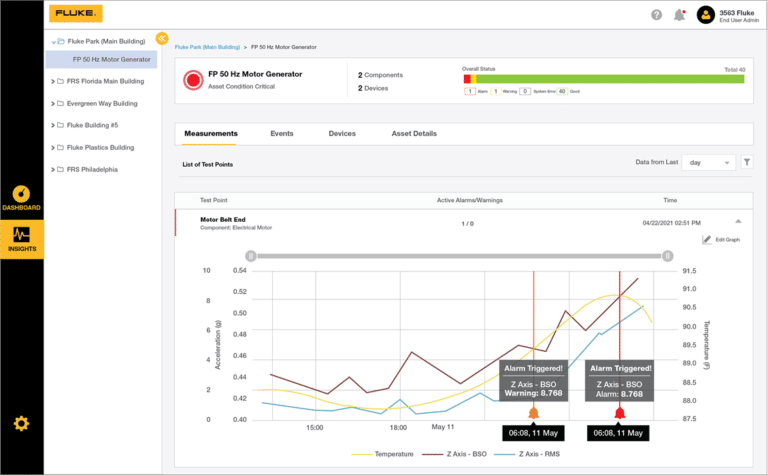

Diagnostic software collects and processes your asset’s vibration data, identifies anomalies, and notifies maintenance teams when an asset needs repairs. When necessary, vibration analysis experts perform a more in-depth diagnosis and advise your crew on the next steps.

Some vibration analysis software communicates directly with a computerized maintenance management system (CMMS). A good CMMS can generate automatic work orders whenever vibration levels cross a predetermined threshold or alarm.

Understanding Vibration

Vibration, the oscillation of an object around a central position, is a key concept for understanding and measuring the health of industrial machinery. All rotating machines generate vibrations, and every asset has its own, unique vibration signature. When a machine’s vibration levels change, it’s usually an indication that the asset needs maintenance.

Because vibration is such an important diagnostic tool, every company that relies on industrial machinery will benefit from using vibration analysis. In fact, vibration analysis is a crucial element of any condition-based monitoring or predictive maintenance program. Done right, vibration analysis can pinpoint the exact location and nature of emerging asset faults, so that maintenance teams can make repairs quickly.

Vibration is typically measured in frequency and amplitude. Vibration frequency, measured in Hertz, describes the number of oscillations per second. Vibration amplitude describes the size of each oscillation, or the distance travelled from the central, resting position.

Vibration analysts study vibration levels in the time domain, to get an overall picture of when vibration peaks are occurring. They also use the Fast Fourier Transform, or FFT, to deconstruct the vibration waveform and plot which frequencies vibration occurs in. Using a combination of different analyses (FFT and waveform) can give analysts useful insights into the health of critical assets.

Types of Vibration Measurement

Vibration is measured in frequency, velocity, acceleration, velocity, and displacement.

Frequency measures the number of oscillations a vibrating object performs per second. Frequency is measured in Hertz.

Displacement measures how far a vibrating object moves from its center. The maximum displacement is referred to as amplitude. Displacement is measured in milimeters.

Velocity measures changes in the rate of displacement and is measured in milimeters per second.

Acceleration measures changes in velocity over time and is also measured in milimeters per second.

Most vibration measurements are taken with a form of accelerometer, which measures the shocks and vibration emitted by assets and components. Many accelerometers – including most wireless sensors – rely on piezoelectric technology, which converts physical vibrations into electrical signals.

Technicians use a wide range of vibration monitoring tools to monitor an asset’s vibration levels. Hand-held monitors, used during route-based maintenance, can capture a snapshot of vibration levels. Wireless vibration sensors can collect vibration data in real-time, throughout a machine’s operation, and can stream that data to the cloud for analysis. Today, most plants use wireless sensors on their critical assets. These sensors can pick up on even subtle changes in vibration levels. They are also easy to mount on assets and component parts, so that they can provide targeted data.

Conducting Vibration Analysis: the Step by Step Process

Every operation is different, but vibration analysis should always include these processes:

Step One: Planning and Implementation

At this stage, teams develop an asset hierarchy and determine which equipment is most critical. This allows the teams to decide which assets they will monitor.

During the implementation stage, you should determine what kind of sensors are most appropriate for your plant, and where you’ll install them. You should also decide which tools you’ll use to analyze your vibration data.

Step Two: Analyzing and Interpreting Data

There are a number of different tools available for analyzing vibration data. A CMMS can organize your data and issue alerts when vibration levels cross a pre-determined threshold. A good CMMS can even auto-generate work orders in response to changes in vibration levels.

Today, artificial intelligence can successfully diagnose machine faults based on vibration data. State-of-the-art tools like Azima DLI can “read” machine tests without any human input, pinpoint machine faults, and even issue detailed recommendations for maintenance crews to make repairs.

Step Three: Repairing Faults

Once your vibration data has been collected and analyzed, maintenance crews can make the necessary repairs. Vibration analysis allows teams to catch new and emerging faults at the earliest possible stages, so that repairs are easy to carry out.

This means that there is a significant decrease in unplanned downtime, since crews can stay ahead of asset failure. It also means that there is greater operational efficiency and a reduction in maintenance costs.

Vibration Analysis Applications

Vibration analysis is a vital ingredient in any proactive maintenance program. By allowing technicians to identify machine faults early, vibration analysis maximizes available resources, increases productivity, and boosts efficiency.

Vibration analysis is a great approach for any rotating asset, or for any industrial machine that includes a rotating component. It is often used to:

- Correct unbalance in rotating assets like compressors and turbines

- Diagnose shaft misalignment

- Identify bearing faults

- Diagnose looseness in rotating equipment

Vibration analysis can also diagnose other asset faults, like defects in pump impellers, motor stators, and electric motor winding, to name just a few examples.

The best AI-powered diagnostic software, like Azima DLI, uses vibration data to diagnose 1200 distinct faults in assets and component parts. The potential applications of this approach are endless.

How Does Vibration Analysis Work with Condition Monitoring?

Condition monitoring and reliability-centered maintenance are proactive maintenance approaches that track asset health by monitoring parameters like vibration, lubrication quality, temperature, and energy consumption. Some condition monitoring programs collect data continuously and stream it to cloud-based software for real-time vibration analysis.

Since vibration analysis helps identify faults early on, it’s at the heart of many successful condition monitoring programs. It alerts maintenance teams to very early signs of equipment degradation by utilizing vibration sensors, vibration analysis software, and expert human analysis. Perhaps it’s obvious, but is this is why it’s considered predictive maintenance.

However, vibration analysis isn’t only for predictive maintenance. You can also use vibration data to diagnose existing machine faults or pinpoint the source of a persistent problem. This process is called root cause failure analysis, or RCFA. Tools that correct rotational unbalance, for example, rely on vibration analysis to locate and remedy the source of unbalance.

What are the Benefits of Vibration Analysis?

Vibration analysis can identify developing machine faults many months before they become critical enough to be considered a failure mode. Early testing gives maintenance teams plenty of time to make repairs without disrupting production schedules or incurring the cost of unexpected downtime.

Vibration analysis can:

- Diagnose existing machine faults

- Determine fault severity levels

- Guide maintenance priorities

- Create an overall picture of asset health

- Drastically reduce machine breakdowns

- Assist in forecasting, budgeting, and inventory

- Improve plant safety

- Reduce sudden, unexpected work stoppages

- Increase asset lifespan

What Can Vibration Analysis Detect?

While there are more than 1,200 identifiable fault conditions, many common machinery failures happen due to one of four factors:

- Unbalance

- Looseness

- Misalignment

- Bearing degradation

A robust vibration analysis program can diagnose these faults before they become severe. The sooner they’re identified, the easier and more cost-effective it will be to repair your equipment.

Here’s how vibrational analysis works in specific cases:

Using Vibration Analysis to Correct Unbalance

Rotational unbalance is a leading cause of damage in rotating assets, like pumps, fans, turbines, and compressors. Even relatively minor unbalance can cause wear and tear on bearings. Machines will often increase energy consumption and overheat, leading to breakdowns.

Rotational unbalance can be the result of a manufacturing defect. But it can also develop over time, due to:

- Faulty mounting

- Heat distortion

- Corrosion or degradation

- Bent or broken shafts

- Missing balance weights

Vibration analysis is one of the best ways to locate the source of unbalance. An excellent rotational balancing tool like the Prüftechnik VibXpert 3 Balancer can take vibration readings in the field and guide maintenance teams through the process of correcting unbalance.

The VibXpert 3 Balancer is sensitive and precise enough to diagnose unbalance early on, when it’s still easy and cost-effective to repair.

Using Vibration Analysis to Identify Shaft Misalignment

Shaft misalignment is another leading cause of failure for motor-driven equipment. In the short term, misalignment can cause leaks, undue wear and tear on parts, and a slowdown in productivity. Over time, misaligned shafts and couplings can break down component parts and cause unplanned shutdowns.

It’s not always easy to achieve precision alignment, but it’s critical. Even seemingly minor misalignment can impact your production schedule and increase operational and maintenance costs. Vibration analysis is one of the best ways to identify misalignment. And a quality laser shaft alignment tool can help resolve the issue to a high degree of precision.

Using Vibration Analysis to Identify Bearing Faults

Over time, industrial machinery will inevitably need to be repaired or replaced. Testing components early, far before they fail, can keep equipment operating longer and make repairs easier to manage.

Vibration analysis is a great way to monitor the health of your equipment bearings and other components. Knowing the type of bearing wear you are experiencing is crucial for root cause failure analysis (RCFA), which helps you diagnose and treat the actual cause of a problem. Diagnostic software can make a big difference here, speeding the process of analyzing your vibration data.

Using vibration analysis means that you’ll replace components proactively. In general, this approach is significantly more cost-effective than an interval-based maintenance approach. Instead of replacing potentially fault-free components on a fixed schedule, you’ll change them as needed which saves you time, labor, and unnecessary costs.

Using Vibration Analysis to Diagnose Looseness

Looseness comes in several different varieties:

- Type A looseness at the feet, baseplate, or foundation.

- Type B looseness of the fasteners or due to cracks in the frame structure.

- Type C looseness caused by improper component fits and wear.

Vibration analysis can help you pinpoint the exact source of looseness, so that you can correct it before the problem leads to a system failure.

Using Vibration Analysis to Diagnose Other Machine Faults

Some of today’s AI-powered software, like the Azima DLI Watchman 360 system, can use vibration data to diagnose hundreds of faults in various systems. Think pump impellers, motor stators, and electric motor winding, to name a few examples.

Experienced technicians can perform an RCFA and diagnose both common and uncommon defects with vibration analysis equipment. The more condition data you have for a machine, the more effectively you can use it to get to the heart of serious faults and keep your operation running.

Overall, vibration analysis equipment can improve safety, reduce unplanned labor hours, cut your budget, and increase productivity. That’s why it’s an essential tool for any condition monitoring or predictive maintenance program.

How to Measure Vibration

Depending on your needs, a simplified monitor or expert handheld vibration analyzer can help you conduct route-based vibration data collection.

Versatile wireless sensors and integrated, wired tools, like the Prüftechnik VibGuard, collect vibration data automatically. The kind of assets you’re measuring, as well as any parameters you’d like to set, can guide your choice of tool.

Here are some of the most helpful tools for measuring vibration levels:

Accelerometers

Accelerometers are at the core of most vibration analysis applications. They measure the shocks and vibrations emitted by an asset or a component.

Most accelerometers have an internal piezoelectric (IEPE) sensor or a capacitive-type (MEMS) sensor. Both convert physical vibrations into electrical signals, which are then recorded and stored as vibration data.

Accelerometers collect data in acceleration, a measure of force. This data can then be converted into velocity, a measure of speed or, displacement a measure of distance.

Vibration Meters

A vibration meter is a simplified handheld device with a built-in accelerometer and a display screen. It provides instant readings of an asset’s overall vibration levels.

Meters provide instant readings of vibration velocity, acceleration, and displacement. Most meters can also store vibration measurements so that you can easily track an asset’s health over time.

Vibration meters are used for day-to-day monitoring. They are a powerful tool in the hands of a skilled industrial machine operator, allowing them to screen for signs of a new or developing machine fault.

Vibration meters can also troubleshoot and diagnose machine faults when an asset already shows signs of trouble. Collecting vibration data can help you pinpoint the cause of an asset malfunction so that your teams can make repairs and get back to work.

Vibration Testers

A vibration tester combines a vibration meter’s functionality with diagnostic capabilities. The tool can measure overall vibration levels and use them to diagnose machine faults on the spot.

A quality vibration tester can also report on fault severity levels and provide specific repair recommendations. For expertise-constrained teams, a vibration tester can go a long way to filling the skills gap.

Vibration Analyzers

Vibration analyzers and vibration testers have many similarities. Both tools provide instant vibration readings, diagnose and assess common faults, and in some cases, can make maintenance recommendations.

However, a vibration analyzer like the VibXpert 3 is an expert tool capable of far more than a simplified vibration tester. In the hands of a skilled vibration analyst, these tools, coupled with powerful analytical software like Omnitrend Center, can give your team a fuller picture of your asset health.

A modern vibration analyzer has multiple channels, allowing it to measure vibration levels instantaneously. In addition to measuring overall vibration levels, it can also take multi-phase measurements and FFT spectrum data. The result is a powerful tool that can efficiently collect high-quality vibration data, pinpoint the exact source of any unbalance quickly, and keep troubleshooting until the issue is corrected.

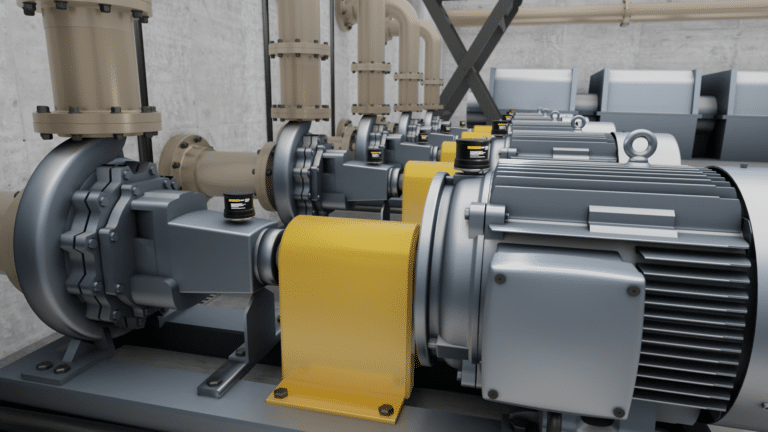

Wireless Vibration Sensors

Wireless vibration systems can monitor many machines with little human intervention. This connected sensor technology integrates vibration monitoring into areas of a plant that would be excluded from a traditional route-based program.

Wireless vibration systems are simple to use: Just mount each sensor on an asset or component and it will collect vibration data around the clock. Each sensor streams data to the cloud for processing via powerful artificial intelligence software.

Wireless vibration sensors can be a key component of predictive maintenance strategies. They provide crucial data to make accurate, specific predictions about when your assets are likely to need repairs. When they’re paired with analytic software, vibration sensors can help teams dramatically reduce shutdowns and increase productivity.

Wired Online Condition Monitoring

Wired online condition monitoring systems are just what they sound like: a network of wired accelerometers, connected by the internet, that report back to an analytic program. Professionals typically use these systems to monitor highly critical, complex machines.

Wired online condition monitoring systems like the Prüftechnik VibGuard IIoT system provide superior monitoring capacity. These systems are engineered to collect high-quality, continuous data on your most critical assets. When that data is processed by powerful software like Omnitrend Center coupled with AI analytical engines, it provides dynamic, in-depth insights into your operation’s critical equipment.

Both wired and wireless vibration sensor systems are effective tools for monitoring your assets. But the system best for your enterprise depends on the size of your operation, criticality of your equipment, and your budget.

How Vibration Analysis Tools Assess Vibration

With the help of a vibration analysis tool, you can study vibration data by assessing two important metrics: the time waveform and the frequency spectrum.

The time waveform presents vibration data as a series of peaks and valleys, mapped against time. When viewed in acceleration, the time waveform is essentially raw data. A waveform graph will indicate exactly when your machine’s peak vibration level occurs. It also indicates how severe the peak vibration is.

While the time waveform is useful, it is complex and difficult to analyze. It does not always provide the concise information you need to diagnose the exact nature of your machine’s condition. That’s where frequency spectrum analysis and FFT come in.

The fast Fourier transform, or FFT, takes your existing waveform data and turns it into frequency data. It creates a graphical representation of all component frequencies with the converted waveform.

Why is this useful? Every component vibrates at its own frequency, and frequency analysis shows you which components are vibrating with the greatest intensity. That way, you can look at individual component frequencies to identify the root cause of a potential failure. The sooner you can identify the problem, the more quickly you can resolve it and resume business as usual.

The Three Key Vibration Analysis Parameters

Vibration experts use three main parameters to assess machine health: vibration displacement, velocity, and acceleration.

Displacement is the distance a vibrating object moves from its center or starting point. It’s the strongest metric to identify faults in the lower frequency range. Displacement is used to diagnose unbalance and journal (or plain) bearing health.

Velocity is the distance a vibrating object moves over a defined time, or speed. It measures mid-level frequencies and can help diagnose the severity level of most machine faults. The velocity reading is commonly the preferred measurement display for condition monitoring because it has a flat amplitude response over a wide frequency range.

Acceleration is a measure of force and refers to the rate at which velocity changes over time. It’s most helpful when measuring very high frequencies. Acceleration can help diagnose early-stage bearing faults and spot issues like cavitation and turbulence in pump systems.

All three parameters are important for building a strong understanding of your asset health. A good vibration measurement tool can display the basics, but the best vibration measurement tools also provide overall vibration levels, time waveform, and FFT data.

How AI Tools Can Amplify Vibration Analysis

If you want even more from your vibration measurement tools, the next generation of AI-enabled equipment offers extraordinary analytic capabilities. The best AI-driven software can quickly diagnose machine faults with an impressive degree of accuracy.

AI solutions like Azima DLI can diagnose 1200 different machine and component faults in almost any kind of asset. It can also determine severity levels and recommend solutions.

AI software can be a game changer for busy teams. Many plants today are already collecting vibration data, but they don’t have the time to analyze it. AI tools can take over the drudgery of analytic review on mostly functional machines, freeing up human experts to focus on more complex problems.

There are benefits to using AI tools long-term, too. The longer AI programs analyze your machine data, the more effective they’ll become at diagnosing problems. Just like human employees, AI software learns from experience. Just make sure that you’re choosing AI software that’s been trained correctly on a large enough data set so that you’re starting with a high baseline of expertise.

Work with the Experts on Vibration Analysis

Software tools can go a long way to diagnose machine faults, but they are not designed to work alone. AI tools and other software are at their best when they work in tandem with human experts.

If your operation is facing labor shortages or needs a boost in expertise, look no further than Prüftechnik. Our team of vibration and condition monitoring experts is ready and willing to help with any aspect of vibration analysis. Whether you’d like to set up a condition monitoring program, choose the right tools, or put your data to use, our team can help. Contact us to speak to a specialist.