Everyone and everything benefits from regular checkups and tune-ups. A trip to the doctor or dentist keeps you in top shape, routine car service prevents breakdowns, and sharpening a blade restores its edge. The same goes for your Prüftechnik condition monitoring and alignment tools — they also need regular calibration to maintain their precision.

Wear and tear, environmental factors, and even the passage of time can subtly affect performance over time. These changes might be undetectable to the eye, but they can quietly impact the accuracy you rely on. With regular calibration — ideally every two years — you can correct equipment drift, which impacts everything from machine performance to data quality.

Where you choose to have your equipment calibrated makes a difference. Not every laboratory in Europe is equipped to deliver the precision you need.

At Prüftechnik’s advanced repair and calibration service center in Ismaning, Germany, we’ve combined cutting-edge technology with 50+ years of expertise to keep your tools performing their best. Let’s take you inside our Ismaning service center to show you what sets it apart as a trusted choice.

6 Advantages of Choosing Prüftechnik’s Calibration Service Center in Ismaning, Germany

1. A Foundation Built for Precision

Calibrating precision instruments requires an exceptionally stable environment. At our center in Ismaning, that stability is built into the foundation.

The foundation is a specialized setup built from seven tons of concrete and 600 kilograms of granite, creating a high-weight base of 7.6 tons. This heavy base is decoupled from the rest of the building, isolating our sensitive equipment from external vibrations due to nearby traffic, train lines, or movement within the building. As a result, calibrations remain consistent and accurate, regardless of environmental factors and external conditions.

2. World-Class Calibration Shakers

Our laboratory is equipped with two state-of-the-art calibration shakers that generate vibrations in the ranges of zero to 200 hertz (Hz) and 5 to 50.000 Hz. This capability allows us to test Prüftechnik vibration sensors beyond standard limits, delivering reliability that extends from initial factory calibration through every re-calibration cycle. For you, this means confidence in results that stay accurate, well beyond standard specifications and tolerances, meeting the demands of even the most rigorous requirements.

3. Guaranteed Accuracy for Your Alignment Tools

Our alignment tools are uniquely designed and can only be re-calibrated by us. By choosing Prüftechnik, you avoid the risks of subpar or inaccurate calibration.

Our services encompass every type of tool used for horizontal and vertical alignment, advanced shaft alignment systems with laser technology, and equipment for motor, pump, and coupling alignment. Key functions, such as laser operation, detection capabilities, and overall system performance, are carefully evaluated and fine-tuned to maintain accuracy within defined tolerances.

4. Fast-Track Calibration

We understand that downtime is costly. That’s why our advanced systems are designed for efficiency, with only one minute needed for each vibration sensor calibration to both factory and post-factory standards. This fast turnaround minimizes the wait for your equipment, quickly getting your tools back into operation.

5. Expertise You Can Rely On

Our ISO 9001:2015 certification demonstrates our adherence to internationally recognized standards, with traceability to SI units through NIST. This provides the foundation for delivering calibration services that meet the highest quality benchmarks.

Behind these standards is our team of highly skilled technicians, whose expertise ensures that every calibration is performed with meticulous attention to detail. Their knowledge of alignment tools and dedication to precision means your equipment is not just compliant but ready to perform reliably in demanding applications.

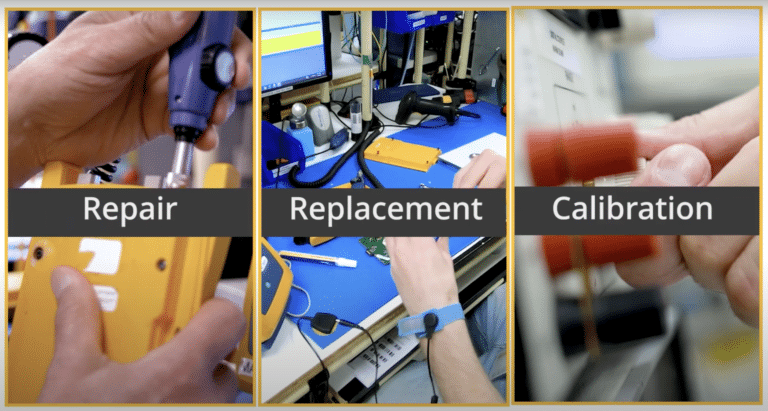

6. Comprehensive, Careful Service

Calibration by our technicians goes beyond basic adjustments. Our service is end-to-end, from thorough cleaning and careful inspection to preventive repairs, firmware updates — and, when necessary, expert advice on optimal tool performance. Every condition monitoring and alignment device receives complete attention, ensuring your tools return to you not just fully calibrated, but thoroughly maintained and ready to support your operations.

Why Choose Prüftechnik Calibration Services?

In short, our calibration service center in Ismaning doesn’t just meet standards — it sets them. With top-of-the-line equipment and a team that’s dedicated to precision, we’re here to make sure your tools perform their best.

Don’t let calibration slide. Reach out today and let us get your tools back in action, ready to deliver precision you can count on.