Condition monitoring tools like vibration sensors can significantly enhance machine reliability. During the pandemic, maintenance organizations capable of using wireless vibration monitoring have managed to thrive. Monitoring equipment health remotely using IIoT-enabled connectivity between people, tools, and systems lets organizations keep workers safe while keeping plants and facilities up and running.

But they didn’t all start out with a fully-fledged vibration program. Many first participated in a wireless vibration sensor pilot to see the benefits before buying sensors.

5 Benefits of a Wireless Vibration Sensor Pilot

Advanced maintenance manufacturers, like Fluke Reliability, often offer pilot programs for their sensors. A pilot lets you start with just a few sensors and see how they work. If you and your organization decide they’re a good fit, you simply add more sensors to expand your condition monitoring program.

It’s a simple, but powerful approach.

1. Kick Start Condition-Based Maintenance with Wireless Vibration Sensors

When you add wireless vibration sensors to your existing preventive maintenance program, you also start a condition-based maintenance (CBM) program, advancing your reliability journey.

Unlike calendar-based maintenance, condition-based maintenance is only performed when needed, preventing technicians from spending hours inspecting healthy machines. Instead, the real-time sensor data lets maintenance personnel continuously view asset condition while technicians address priority maintenance needs.

Wireless vibration sensors support condition-based maintenance by continuously monitoring asset health. A notification is automatically sent if the sensor detects abnormal machine vibration. Teams can then make data-driven decisions and plan actions. Parts can be ordered or maintenance scheduled immediately to avoid asset failure.

2. Condition Monitoring Saves Time and Money

Technological advances are making wireless vibration sensors much more affordable and powerful. These modern vibration sensors overcome some earlier drawbacks. For instance, they offer increased sensor battery life and reduce the need for substantial bandwidth. Today’s industrial vibration sensors can also monitor a broad array of machines.

And as your team monitors for excessive vibration in rotating equipment, you can identify problems early, saving time and money.

3. Piezo Vibration Monitoring Sensors Pack More Punch

Some vibration sensors contain powerful built-in piezoelectric technology and other advancements. These piezo sensors deliver high-resolution, high-frequency readings that enable vibration analysis. They supply more in-depth data than the most common sensor, the microelectromechanical system (or MEMS) sensor.

Higher-quality analysis vibration monitoring sensors like the wireless Fluke 3563 Analysis Vibration Sensor combine piezoelectricity and MEMS sensors. It gathers more specific data and can identify frequency readings of up to 10,000 Hz or more.

4. Vibration Analysis Can Identify the Exact Fault

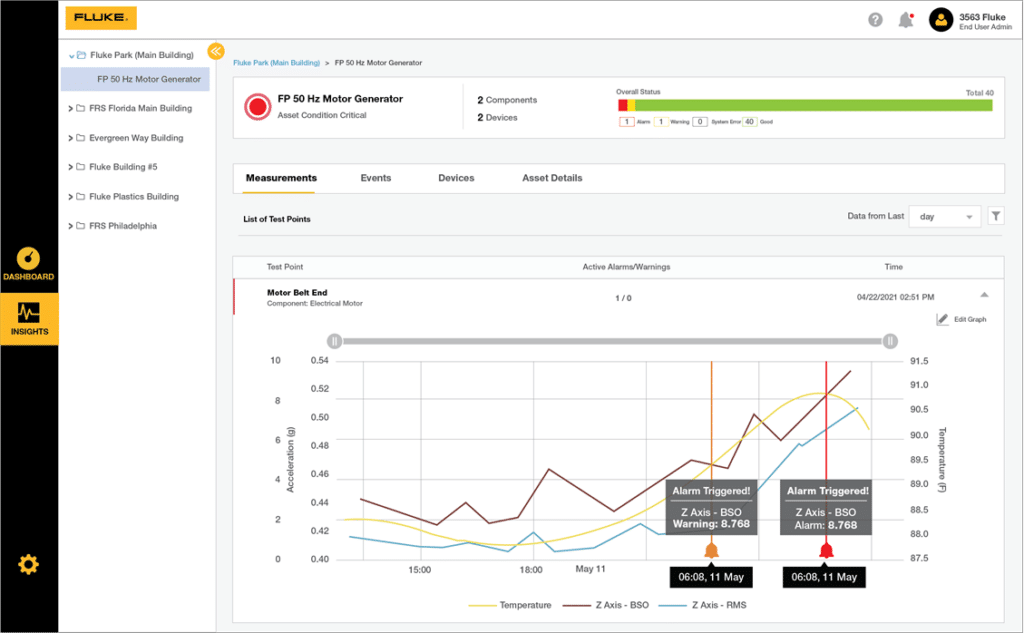

Vibration analysis sensors, like the Fluke 3563, offer maintenance professionals an understandable way to view and recognize trends, anomalies, and patterns in data. With this information, users can identify the machine causing the problem and the four most common faults: bearing damage, misalignment, looseness, and imbalance.

Ultimately, vibration sensors extend machine peak operating performance, life cycle and help optimize valuable resources.

5. Easily Install Wireless Vibration Sensors During the Pilot

Often, sensor installations can be time-consuming and confusing. But today’s wireless vibration monitoring sensors come with predefined data thresholds. Or you can customize them to fit individual preferences.

Fluke Reliability’s vibration sensors are simple to install and configure, and organizations can use our expert services. Once implemented, users can view data instantly in real-time via the application software to gain insights into machinery conditions.