Maintenance professionals around the globe have embraced Reliability Centered Maintenance (RCM) in their operations. The principles of Reliability Centered Maintenance can positively impact your bottom line by reducing downtime, increasing equipment lifespan, and reducing unnecessary repairs.

Maintenance Evolution

Maintenance wasn’t invented in this century. People have been repairing stuff nearly as long as there have been pre-civilized societies. It’s how maintenance is planned that has separated pre-modern from modernized.

Between the Industrial Revolution and World War II, equipment was purely mechanical and mechanized.

Equipment was well-engineered and low-tech (compared to recent equipment). It was pretty reliable in the first place and more straightforward to repair after breakdowns. Unskilled labor was in high demand then, as it didn’t take much experience to clean, service, or lubricate machinery.

Post-World War II industrial machinery took on new reliability requirements. The wartime need for production dropped. People were needed less in those maintenance roles and, by the ’50s, equipment started getting more complex. In later decades, they’d become augmented with computers. This increase in automation dropped the cost and need of human capital. With fewer people needed to maintain machines, maintenance managers also started looking at asset management as a whole life cycle.

The Beginnings of Reliability Centered Maintenance

In the last quarter of the 20th century, Reliability Centered Maintenance rose as an established process in the industrial world. Its principles of risk and asset lifecycle management have spread and improved operations around the globe. During this era, maintenance pros leveraged more technology to alleviate worker gaps than in previous generations. And more than any previous generations, they leaned into new techniques for avoiding machine failures.

We are currently in this ongoing evolution called Industry 4.0 or Industrial Internet of Things (IIoT). And in this future we’re building, digital technologies will have more power over machines. Sensors will monitor to predict a failure while connected software diagnoses the potential fault and provides prescriptive maintenance options.

What does Reliability Centered Maintenance Mean?

Reliability Centered Maintenance is a strategy that integrates contextual asset function and asset criticality into maintenance planning. This way of strategizing assets doesn’t give the largest or most complex assets the most attention but the ones required to keep operational functionality sufficiently optimal.

So, your fan blower that supports HVAC or a pump for the refrigeration unit may have a higher criticality than a conveyor motor on a rarely used line.

Reliability Centered Maintenance was first developed by three engineers: Tom Matteson, Howard Heap, and Stanley Nowlan. They created a study for aircraft maintenance and reliability requirements for United Airlines, later sponsored by the U.S. Department of Defense. The study — which is still available online in RCM PDF part 1, RCM PDF part 2, and RCM PDF part 3 — changed how maintenance teams think about reliability and uptime.

Managing risks with Reliability Centered Maintenance

Reliability Centered Maintenance, while complex, has a relatively simple start. The process defines equipment in three categories by its threat and impacts to 1) safety, 2) operations, and 3) maintenance budgets.

So, that fan blower in your HVAC could impact the safety of workers and their ability to operate, which would also affect budgets. In contrast, the spare conveyor line motor is not a threat to any of those three.

As part of the Reliability Centered Maintenance process, there are a number of risk management strategies:

- Reactive maintenance: is the maintenance repair work done as an immediate response to an asset failure, normally without planning and scheduling.

- Preventive maintenance: where a calendar or usage statistic, such as months or miles, is used to determine when maintenance should occur.

- Predictive maintenance: is a strategy based on the actual condition of the asset as determined from non-invasive measurements (wireless sensors)

- Corrective maintenance: is where unplanned maintenance tasks are performed to restore the functional capabilities of failed or malfunctioning equipment or systems.

- Run-to-failure maintenance: is deliberate decision to allow an equipment to operate until it fails.

- Detective maintenance — where one frequently checks equipment to achieve the function or job of an asset

Your strategy may involve allowing specific assets to fail. When they fail, you simply swap it out with extras you have on hand. Other assets may be so critical to your operation that they have predictive maintenance sensors sending you information into asset health and functionality.

Reliability Centered Maintenance in Your Operation

Implementing RCM is no easy task. It’s a complicated and complex strategy that guides your operational processes toward peak uptime. Condition monitoring, FMEA, and designing for reliability all help teams predict, diagnose, and work toward sustained or increased capacity.

The most recent challenge is selecting the appropriate tools for the equipment you have. Vibration monitoring has been a star performer due to its location on the P-F Curve’s early detection area. Condition monitoring with vibration sensors and handheld tools informs maintenance teams, like yours, about impending faults with more than enough time to identify problems and plan repairs.

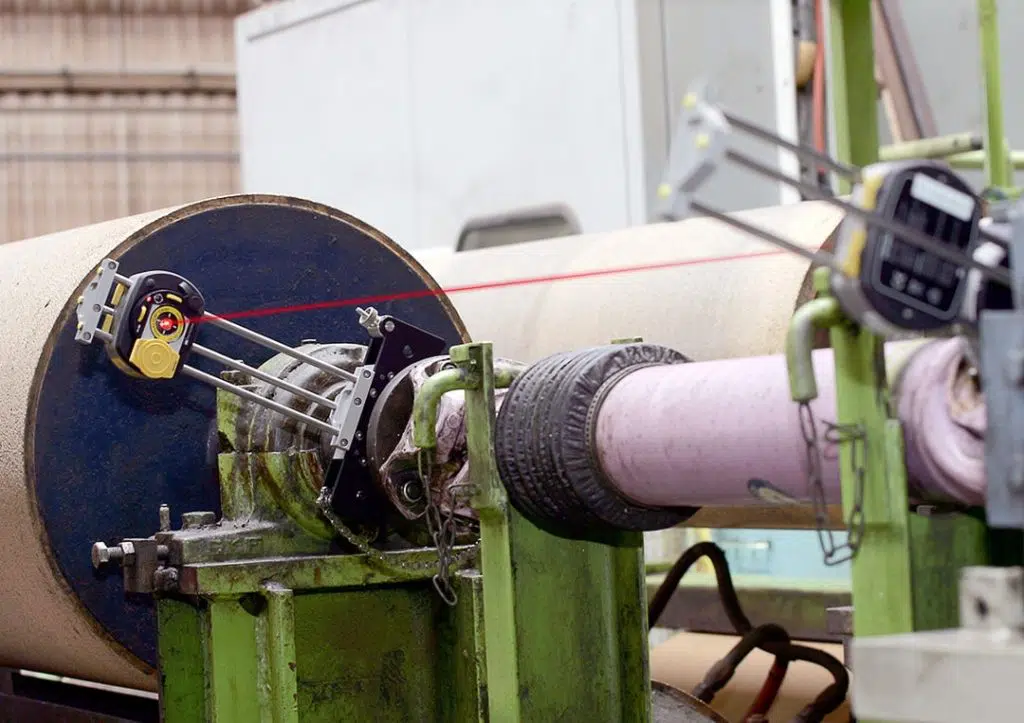

One of the more complex kinds of repairs is aligning rotating assets. Alignment starts at the ground up — at the asset’s foundation. If assets aren’t planarly aligned, nothing above it will be either. Then there are the rotating shafts themselves. Conveyor rollers are aligned to the machine as a whole and each other, making their alignment much more tedious. Alignment is a multifaceted job that requires multiple people, lots of stopping and checking, and post-work reviews. And that’s why maintenance teams often overlook some key preventive maintenance alignment tasks.

Reliable rotating assets

Not only has it historically been a difficult job, but getting the precision to required accuracy was difficult with common but inaccurate tools. When planning for reliability, though, alignment is integral at the commissioning stage and throughout asset life. When you ensure your rotating assets are properly aligned, you can:

- Reduce energy consumption by up to 10%

- Decrease repair incidents by up to 65% on mechanical seals and 30% on pump repairs

- Increase bearing lifecycle by up to 50%

In a survey conducted by a leading rotating equipment service organizer, only 7% of 160 randomly chosen machines were within acceptable alignment limits.

Older methods are only as accurate as the human eye — around 1/10mm resolution — when the required resolution is 1/100mm.

Shaft alignment tools

Laser Alignment tools are the perfect tools for accessible and easy-to-understand alignment procedures and post-alignment reporting. The industry-leading RotAlign Touch and the more full-featured ShaftAlign Touch are single-laser tools to help you elongate mean-time-to-failure with precise, repeatable alignment.

Peak RGA Alignment Service

Sometimes, for larger machines, calling the experts is your best choice. Their experience can help you decrease overall downtime for big jobs. Equipment—such as steel, paper, or rubber calendering machines—may be your most significant burden, but it’s just a Tuesday for our experts. Prüftechnik’s Peak RGA service leverages gyroscopic technology to give you the best in precision alignment.

Fluke Reliability & Prüftechnik solutions

Prüftechnik invented single-laser shaft alignment tools. As part of Fluke Reliability, they are still the leading brand in laser shaft alignment products and services. Combining their inventive innovations with the rugged trustworthiness of Fluke.

If you’re ready to learn more about our sensors, software, tools, or services, contact us to speak a specialist.